Information is POWER... learn the facts!!

sorry this took so long...

for now this should work, I may need to have the timing cover, and water pump ones made... but I could make those if I so choose... OR if you "osmerjosmer" make them... would you make me a set, or point me to whom you use...

more to come....

Information is POWER... learn the facts!!

Awesome I'm glad they could make it I was playing around with a 3d printer to make a die for gaskets on another engine but it didn't work too well but I'm going to try again about how much did they charge to make those gaskets

Sent from my SM-G935V using Tapatalk

I like how you think...

I have a fabricator friend.... The distributor is to be turned into a cam sensor. Inside at the base of the distributor there is a multi spoke wheel, and a pick up. The multi spoke wheel will have all but one of the spokes removed, and then a simple cover will be added after the distributor housing, and top portion of the shaft is removed.

Now this is a development.....

About the time the engine arrived, I was still working on a transmission solution. The easy answer appeared again on Yahoo Japan...

So I bought it.

While it does provide me a transmission solution, at the time I wasn't aware of THIS:

I've spoken with the adapter's manufacturer, and he believes the 5V-EU bell housing can also be adapted!!! Since the bellhousing doesn't get modified, I'm left now with a "2 in 1" option. I can use the manual trans set up while I'm still able, and if need be, I can swap the auto back in at a future point in time IF I can no longer drive a shift, or I'd want to for some other reason...???

DEFINITELY more to come.......

Information is POWER... learn the facts!!

Looks to me that you have a one-tooth and a multi-tooth wheel already there in the dissy, so really no need to go to the trouble of fitting a separate crank sensor. You can still remove the high tension stuff and go COP if you don't want plug wires

Cheers... jondee86

Hmmm interesting... there is a lot of damage inside, the top single tooth I believe has no structure anymore for the pick-up to mount too - but I have to double check. As to using the lower spoke ring as a crank sensor.... it turns half speed of the crank, so how would that work with a tooth missing?? Would it be 2 teeth missing(opposite each other?)

Information is POWER... learn the facts!!

The consensus is that for full sequential operation you need both a cam and a crank trigger. The one-tooth cam trigger tells the ECU when the engine is at TDC (compression stroke) on the reference cylinder. Having two missing teeth at 180 deg on the multi-tooth trigger wheel would not allow the ECU to differentiate between TDC on the compression stroke or on the exhaust stroke.

Without a TDC (home or reset) signal, you will be limited to batch fired injection and wasted spark ignition.

I do remember reading every now and then of people building crafty systems that allow both cam and crank signals to be derived from a single trigger wheel, but that would involve custom electronics and it is not something I would recommend.

Cheers... jondee86

That is why I was going to run the "conventional" crank trigger system, and then use a single contact off the dist(cam). Basically it is what I have in my 4AGE, I have a toothed crank wheel, and I have a modified dist with just a single trigger inside. I'm running sequential injection, and wasted spark. It seems to work....???

I'm open to ideas... my strength isn't in the management side of things.

Also, in this application, I'm not a fan of COPS. The valve covers require plug wires, wasted spark towers would do, so would custom LS1 type wired coils. As to going distributor-less (you didn't ask - but it has been asked) - it is a blessing as it would likely have caused some packaging issues when I finally do find a chassis to put it in.

Information is POWER... learn the facts!!

Your original idea will work. A trigger wheel on the crank and a single tooth in the base of the dissy will provide all the information that the ECU requires to run full sequential on 4-cylinders. However, your 8-cylinder engine would require an ECU with eight ignition and eight injector outputs to run full sequential. So typically on eight cylinders you will use batch fire (maybe semi-sequential) injection and wasted spark ignition using an ECU with four outputs.

Alternatively, if you put a 36-1 trigger wheel on the crank you could use a Ford EDIS system that does not require a cam trigger. Bit more messing around but cheap and readily available. If this is a carbed engine that would be all you need. If you run some form of injection then a 36-1 wheel on its own will still run the engine no problems. You wouldn't have sequential anything but that doesn't have any significant impact on performance.

I'd suggest that you go ahead with the crank trigger wheel plus one-tooth cam trigger. Then you are leaving all your options open.

Cheers... jondee86

As of now it will be far more efficient(and less dangerous) with the fuel injection, then trying to build a manifold from the efi manifold for a carb. Building a new manifold from scratch is also not likely an option ($$$$)

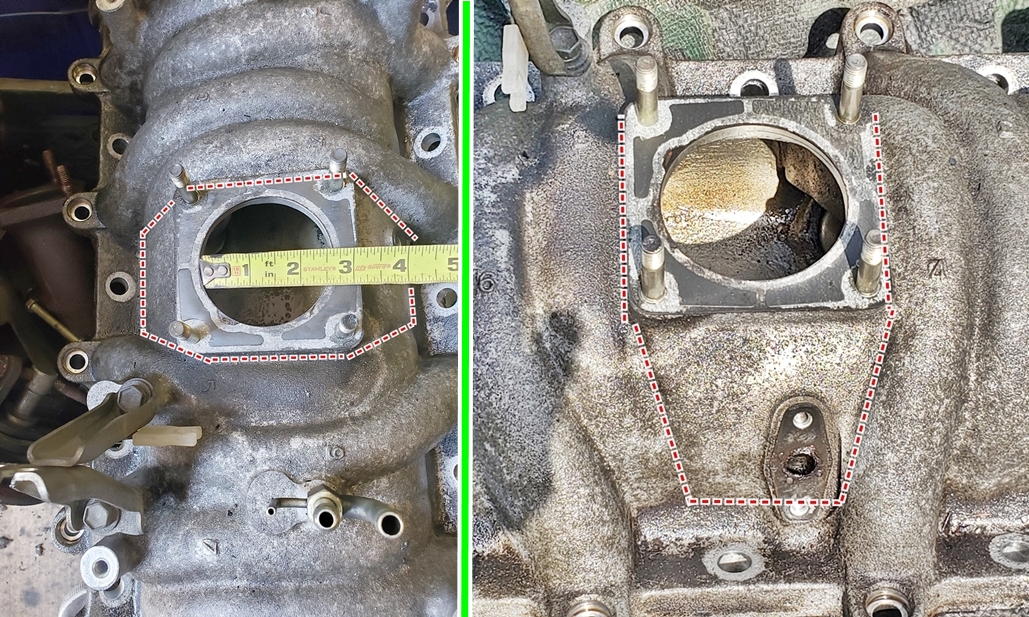

There is room to install a large throttle body assembly. The current T/B pad may need to be removed for a larger one. I've been advised that a 3"(76mm) throttle body is good for about 300hp n/a.

Information is POWER... learn the facts!!

Hell yeah... keep the injection

Unless the OEM size throttle is known to be a restriction within the normal operating range of the engine, I would be careful about increasing the size. The only measureable benefit will be a bit less pressure drop at WOT and high rpm. The potential downside is loss of driveabilty at low to medium engine speeds.

I'd guess that considering the type of vehicle this engine was factory fitted into, the design goal was a smooth torquey engine with the emphasis on low to medium engine speed (city driving) performance. The throttle size would have been selected with this in mind.

A larger throttle basically means that the manifold pressure will reach atmospheric earlier (with less rotation of the throttle plate). Once the manifold pressure is at atmospheric at any particular rpm, opening the throttle further has no effect. This is known as a loss of control authority

The engine rpm and air demand has to increase until the throttle is creating some restriction before the throttle can regain control authority over airflow. When the the throttle is wide open it has no control authority at any rpm. Airflow is only limited by the restriction of the total inlet tract (think diesel engine).

So.... WTF does this mean ???? Just that the throttle size needs to be selected to suit the engines airflow needs... standard hot rodding practice for V8 engines I believe.

Cheers... jondee86

PS: Yes I know... c**ts mad, but it is cold, wet, miserable Saturday morning here and I'm bored

@oldeskewltoy when you got the gaskets made did they save a print for them I'm ready to get some and I wanted to ask if they still had them on file. Thanks

Sent from my SM-G935V using Tapatalk

Bookmarks