Cheers guys.

Picked up some earls gear for the turbo and I think I've got them set where I want them.

Oil feed is going to run round the mack then across to the oil pressure sender which i have tee'd. Thinking of getting some copper pipe made up to go from the tee to the back of the engine to meet up with the braided oil line.

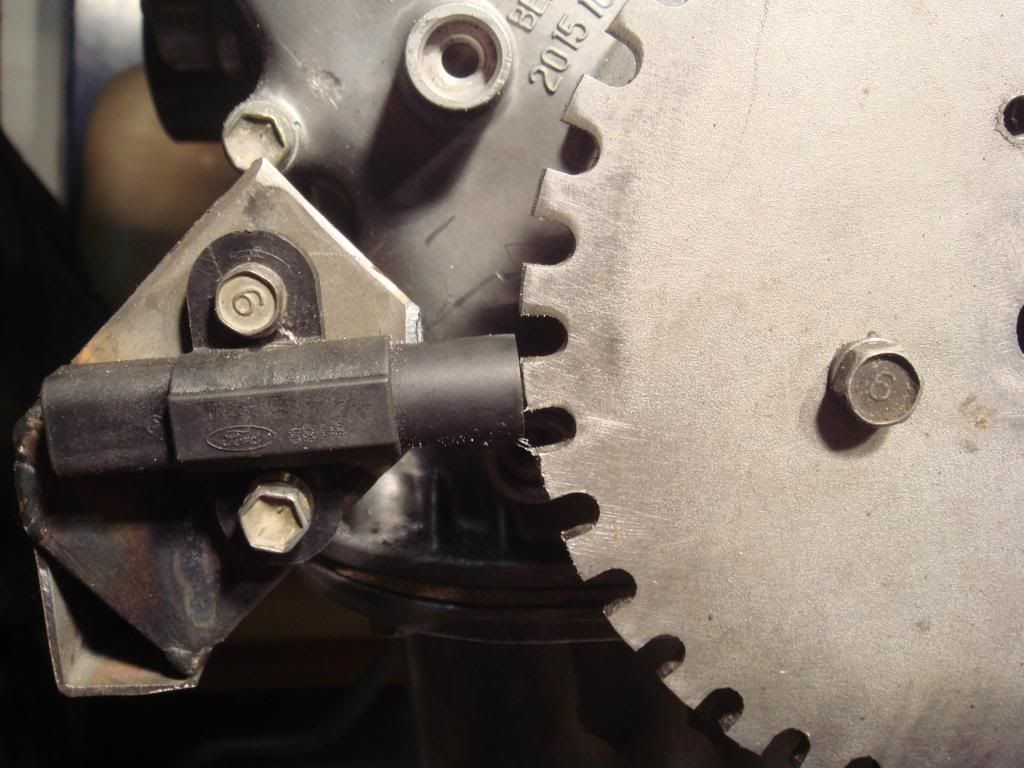

Water lines are going to go directly from the water pump to the part pictured in the back of the head. Can anyone see any problems with this? Heat? Flow?

Wish i knew where all the water went and what directions it was meant to flow in the engine.

Reply With Quote

Reply With Quote

)

)

)

) Bring it up to 35deg advance and the engine runs normal again and throttle response is back

Bring it up to 35deg advance and the engine runs normal again and throttle response is back  I pull about 6 degrees back out by 12 pounds of boost and its a package that gives me a much needed giggle to and from the drudgery of work!

I pull about 6 degrees back out by 12 pounds of boost and its a package that gives me a much needed giggle to and from the drudgery of work!

Bookmarks