you'll need GZ20 mounts? MZ20 suggests an 7MGE was the donor engine?

Hey all, im trial fitting my engine mounts into the celica ot make sure its all going to line up properly 2m...and im not sure now, it looks wrong to me

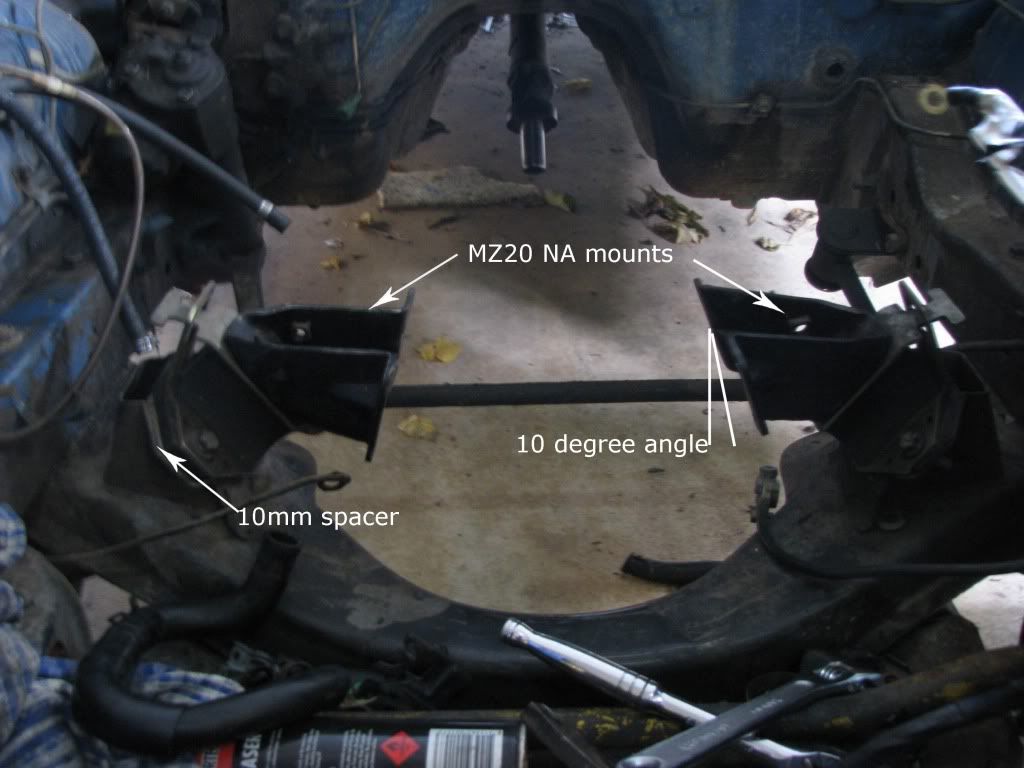

Engine mounts are from a NA soarer, with new rubbers.

It might be fine, but it just looks really weird to me.

Anyone else done this?

Also easiest way to install the engine>?

Im thinking bolting the mount assembly to the block and lower it into the bay for ease....

heres a piccy (sorry, flash was flat~!)

Rotaries are cool...so why are their owners such cocks>>?

you'll need GZ20 mounts? MZ20 suggests an 7MGE was the donor engine?

....yes, that was a little retarded on my part...sorry, theyre GZ20's

Rotaries are cool...so why are their owners such cocks>>?

They look like the right ones... but no idea why you've got that angle... I can only assume that there's a difference between GZ20 mounts, and 1GGE mounts... Isn't there naturally aspirated, and turbo'd GZ20s? Make sure the mounts are from a naturally aspirated engine.

As for mounting it up, bolt up the GZ20/1GGE mounts to the engine, you could leave the 18RC mounts bolted to the engine mounts too, but that'll make it a bit more difficult to lower in. And you shouldn't need the 10mm spacer too if you bought the rubber mounts from Repco... they're a little thicker then the std ones... I don't have a spacer in mine, and there's no clearance issues.

Cheers

'77 RA28LT #2 ← 2.2L 18RG...

they'll straighten up.....rubber will take out the angles..........

What if you swap the sides & turn them up the other way?

fwiw: those universal fit rubber isolators are not good with high-torque motors that twist/rotate in the engine bay.

My 18RTE smashed two sets of them - one side (motor pulls away from mount when motor is revved) tears along a rubber-to-metal face, the other side gets compressed (when motor revs up) then starts to crumbles as the other failed mount permits too much movement.

On the way back from dubbo, i ended up with the passenger side completely failed and turbo dump pipe resting on the steering drag link.

The standard mounts are lower profile and allow less movement when one mount fails.

Blake, if you rely on the rubber to take out the angle, your just starting out with a massive stress in there...

Peter, if you turn them up the other way (if i'm understanding it correctly) they'll be roughly 90* to where they are now (facing to the sky)...

Charles, my 18RG did the same thing on the intake side... but so far, it's only killed one mount. Then again, they lasted nearly 12 months under my 1G with no signs of failure...

'77 RA28LT #2 ← 2.2L 18RG...

I meant only the long steel mounts. The mounting faces would then face more to the vertical. I've never seen a set of mounts that face down. The faces on the block couldn't be that angle?

Also, the mounts you have are very thick. This probably reinforces the statements above about failures. They could allow a lot of twist if soft. Mackay sell universal rubber mounts. Look on the web.

I am assuming you mean the rubber? If so that is how i run them in a 1GGTE Ra28 the metal tab is facing the bottom of the car. Mine are also Repco mounts and do not have to have the 10mm spacer in. My 1GGTE appears to fit fine in the engine bay and clears the steering box by 10 or so mm.Originally Posted by RAd28

Also i found if you leave the mounts on the engine and rubbers i found it is easier to line it up in the engine bay (even though its a bit harder to get the enginer 'over' the front of the car.

Cheers,

Steve

1977 RA28 with 1GGTE - Now Driveable! Just with speed holes and no doors

If the mounts actually bolt to the 1g and they are the correct mounts then perhaps everyone elses 1g mounts look the same when they aren't bolted to the motor.

Easy solution if you want to use those mounts and you don't want to twist your rubber isolators is to chop the steel mounts off the crossmember, cut them to the right angle, sit the motor in the car with the mounts attached and then reweld them to the crossmember. Benefits of this will be that the motor will sit lower and in a position you actually want it to. Even better yet put rack and pinion in it

stidnam

Hi mate, these are my old mounts and yes they did work perfectly, im pretty sure you've got the rubber mounts up-side down (not sure if this will correct the angle). When i had the motor dropped in for the first time they were the same taller rubber mounts used with the 10ml spacers so i dont know how your getting that angle. Just bolt the steel mounts to the block, drop the motor onto the rubber mounts and it will sit fine.

P.S i only got your msg through e-mail not here on toymods so sorry for the delay in the msg

edit - when you drop the motor in make sure you have the rubber mounts bolted to the crossmember loosely for easement otherwise it will take forever.

RA23 1JZ VVTi 373hp - SOLD

12.4 @ 110mph

THE EVOROLLA262.9hp - SOLD

JZ parts facebook page - https://www.facebook.com/groups/524841910926804/

Rather then just speculating, I figured I'd take some shots of the 1G in my engine bay. It looks fine, the mounting faces on the block seem to have some angle too them.

Looking at those now, I might have a bit too much strain in those rubber ones, and I might acctually have a crack in the right one (2nd image)...

Hope this helps anyways...

'77 RA28LT #2 ← 2.2L 18RG...

I reckon even the mounts above aren't right - that's why they are starting to split. The mounts should be in compression and not shear. Either they need to go lower down or the metal engine bracket longer to go out further so the load starts to compress the mount.

your probably right... perhaps the 10mm spacer would help out there... atleast it answers the question regarding the angle.

Bare in mind too, the rubber mounts above are more then are almost 12 months old, and that may not acctually be a split... I'll have another look later... It could just be a bit of crap on the mount...

'77 RA28LT #2 ← 2.2L 18RG...

Bookmarks