Originally Posted by from another forum

Now I (we all) know about this kind of case/latchOriginally Posted by from another forum

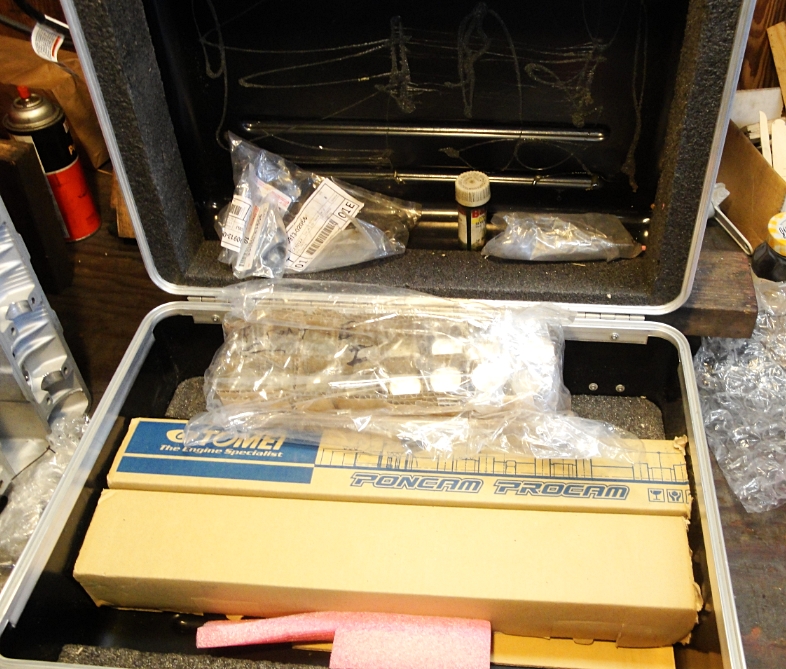

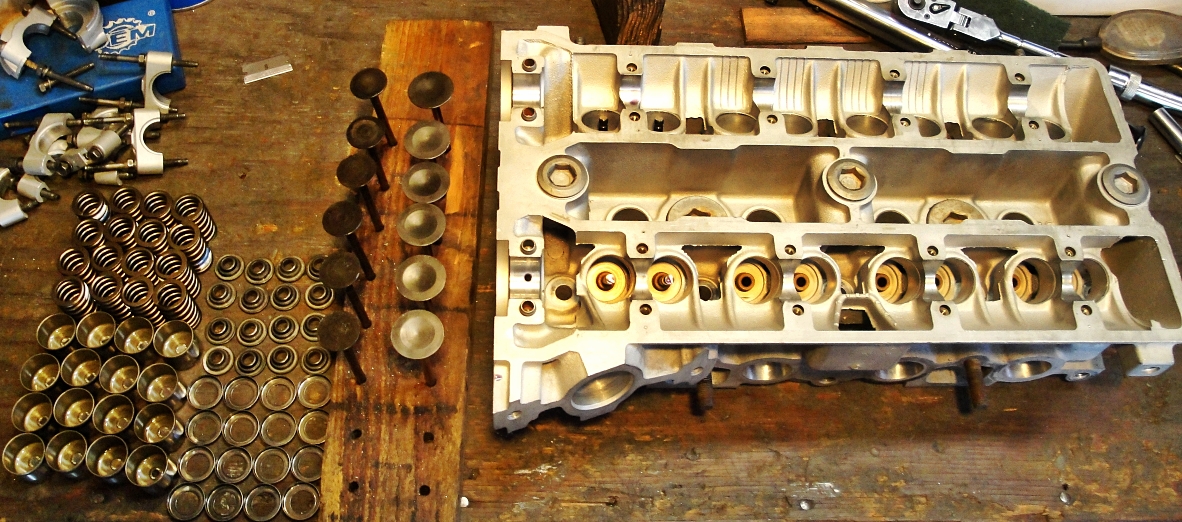

While OST-031 is being cleaned and pressure checked, it gives me a few days to work on OST-030...

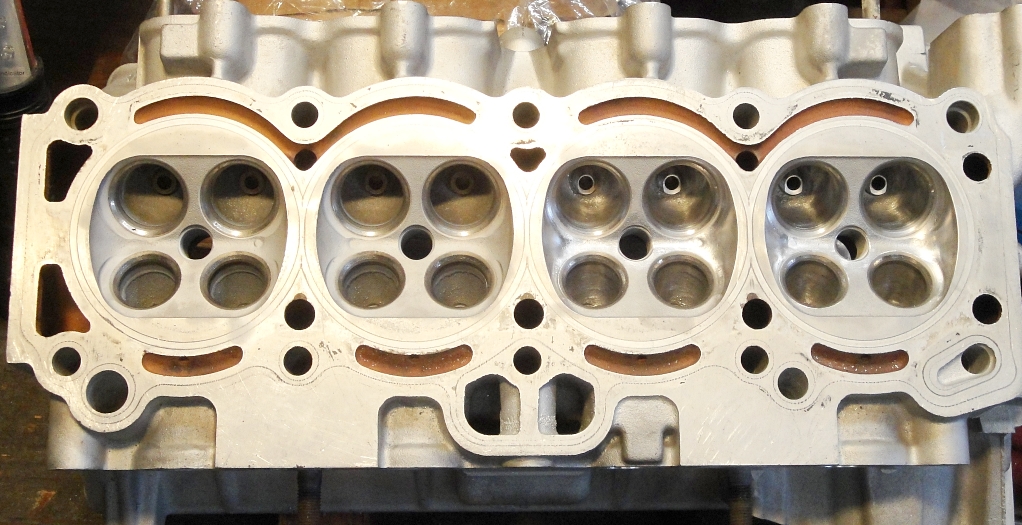

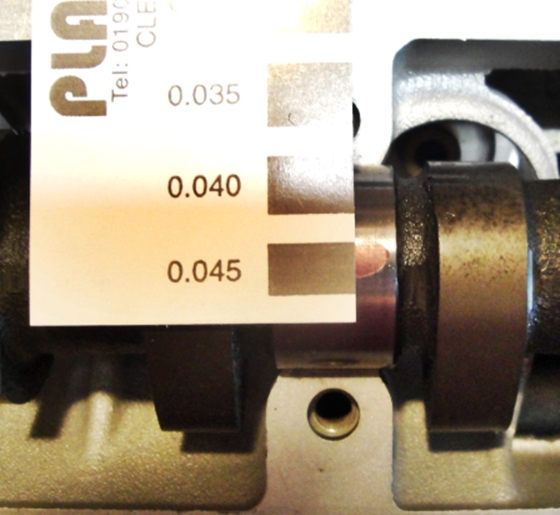

Besides the Poncams, my client is using a piston with a 3.2cc dome. He has to check, but believes he has .005" of positive deck - piston slightly ABOVE the blocks surface. He wants to run a squish of .040".

What chamber volume does he need for a 11.3 to 1 compression ratio?

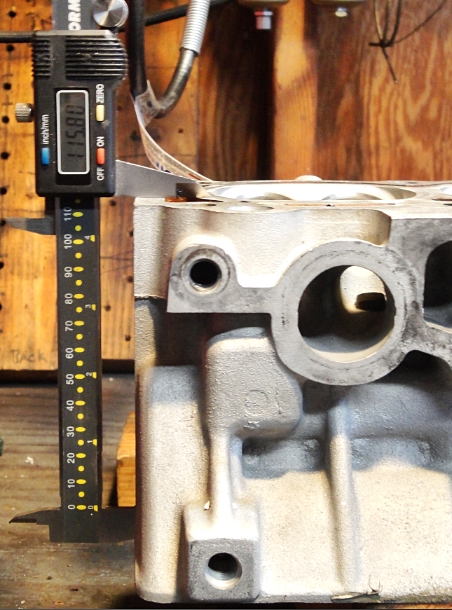

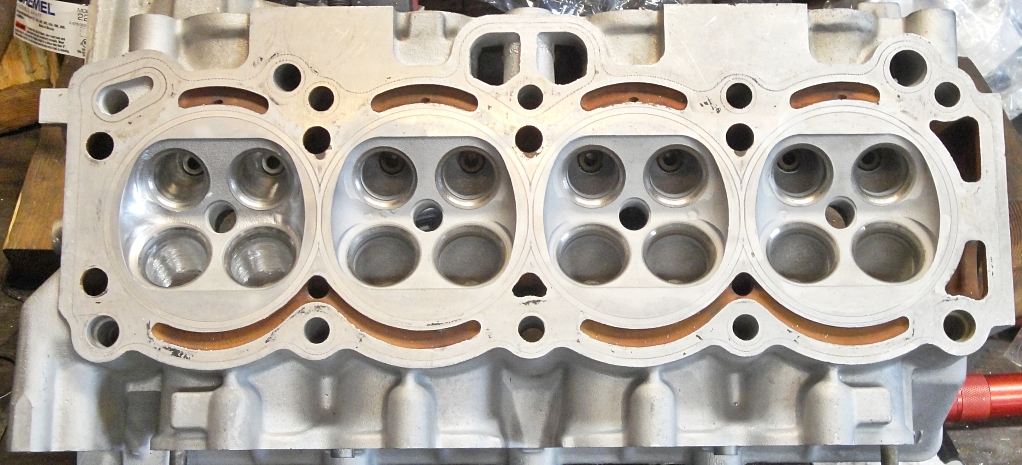

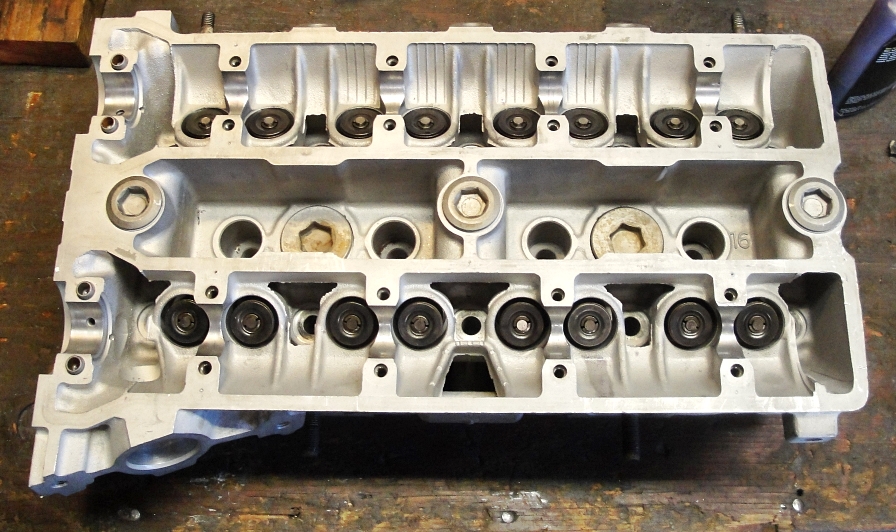

My clients said his head had been already run through the mill once... .008"

Seems pretty close to me....

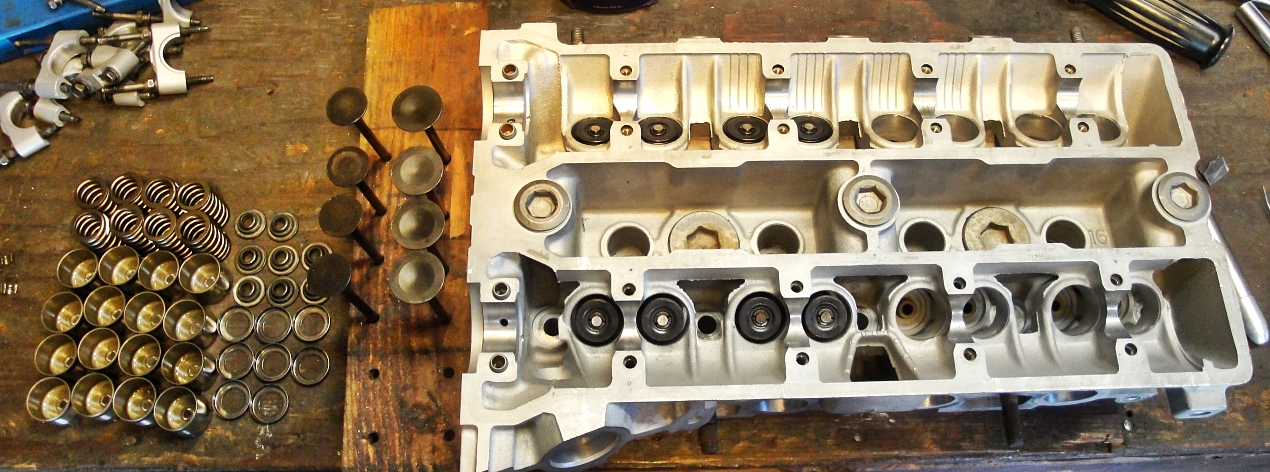

btw... look at the "round" exhaust port...

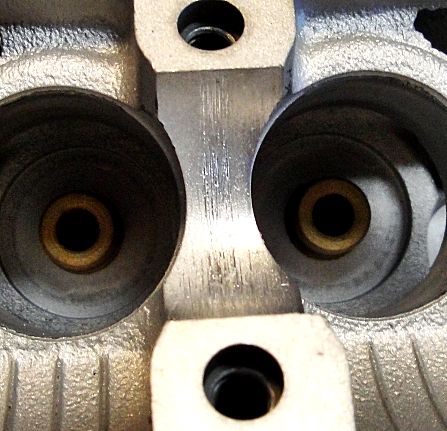

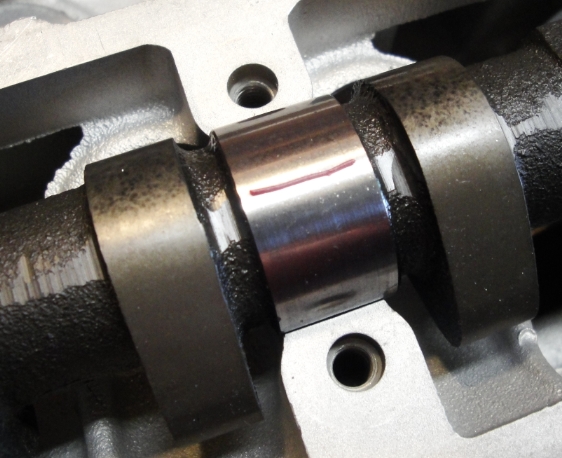

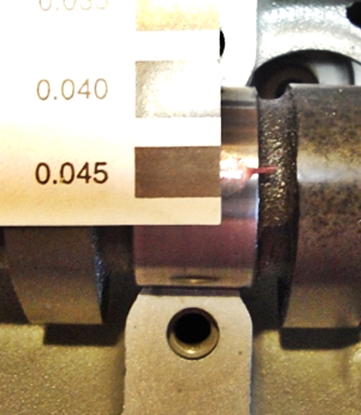

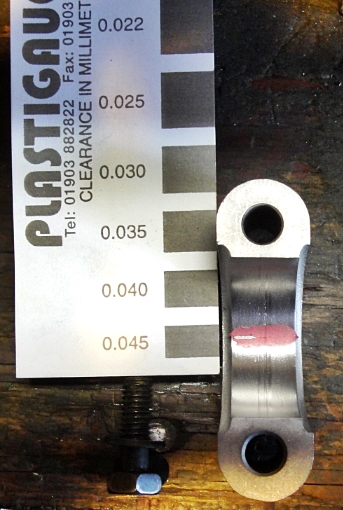

All the cam journals look pretty much the same as this...

Since MR2tailbreaker noticed a "small" problem in his cam and journal clearances using the Poncams, I'll be checking these journals for similar issues.....

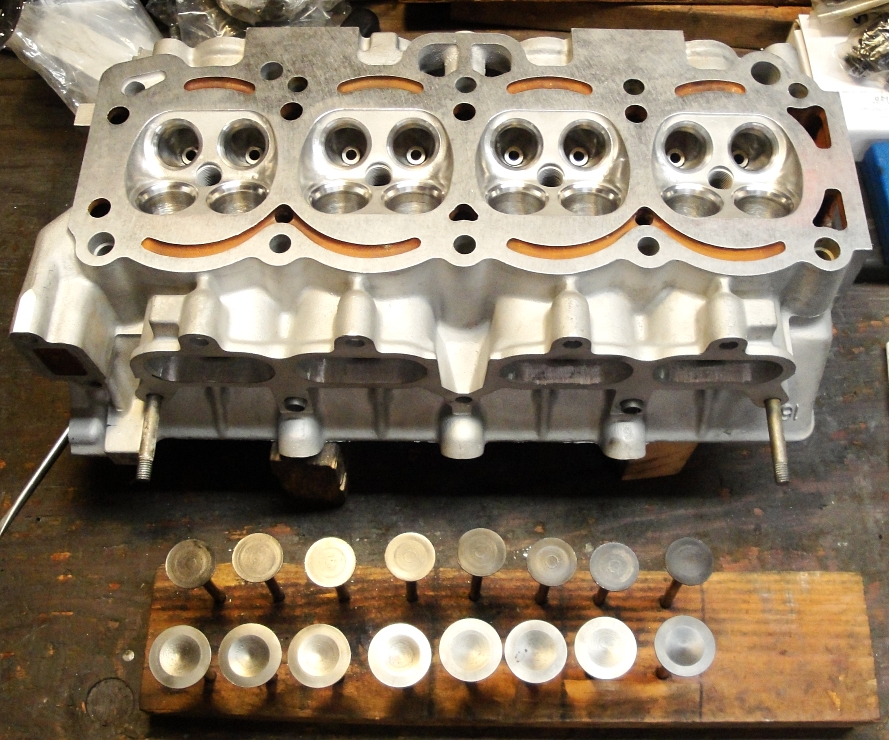

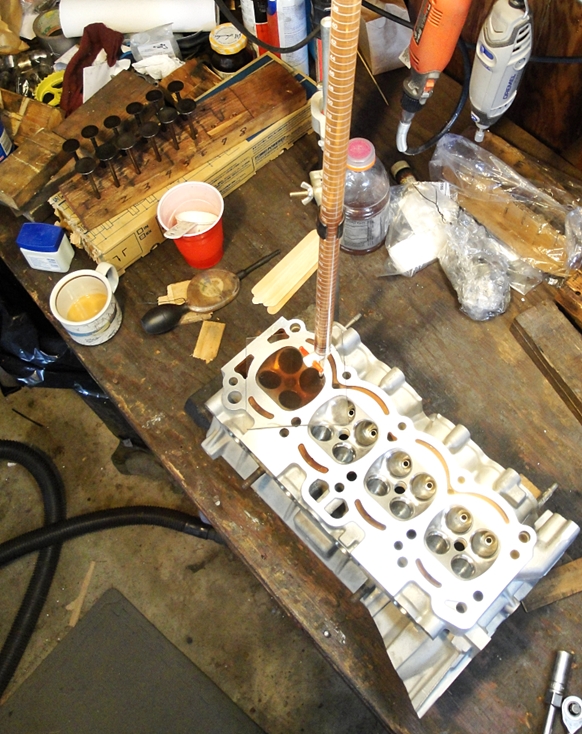

Work begins on the bowls and seats of chamber #1

More to come....

Reply With Quote

Reply With Quote

Bookmarks