#1 is the filler cap.

#2 is the breather. It should go to a catch-can in case of overflow.

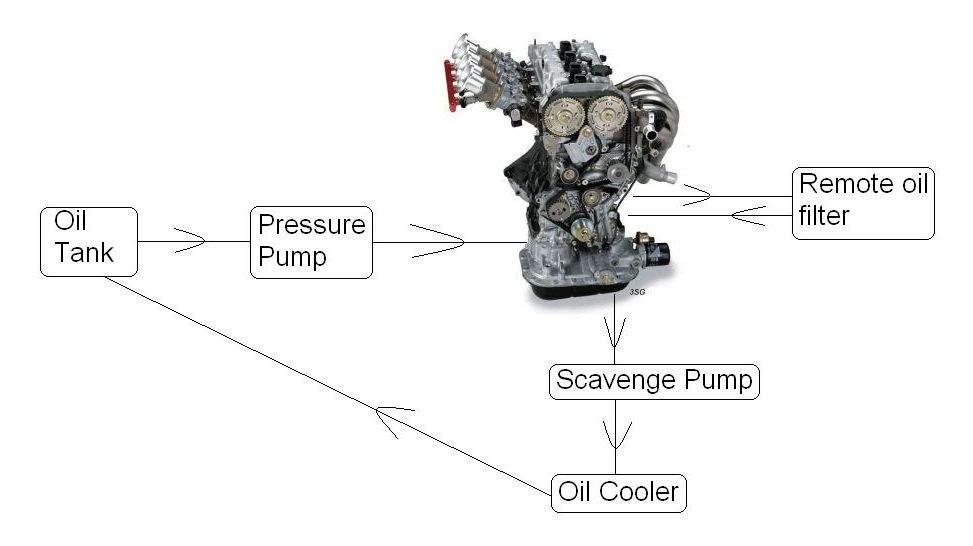

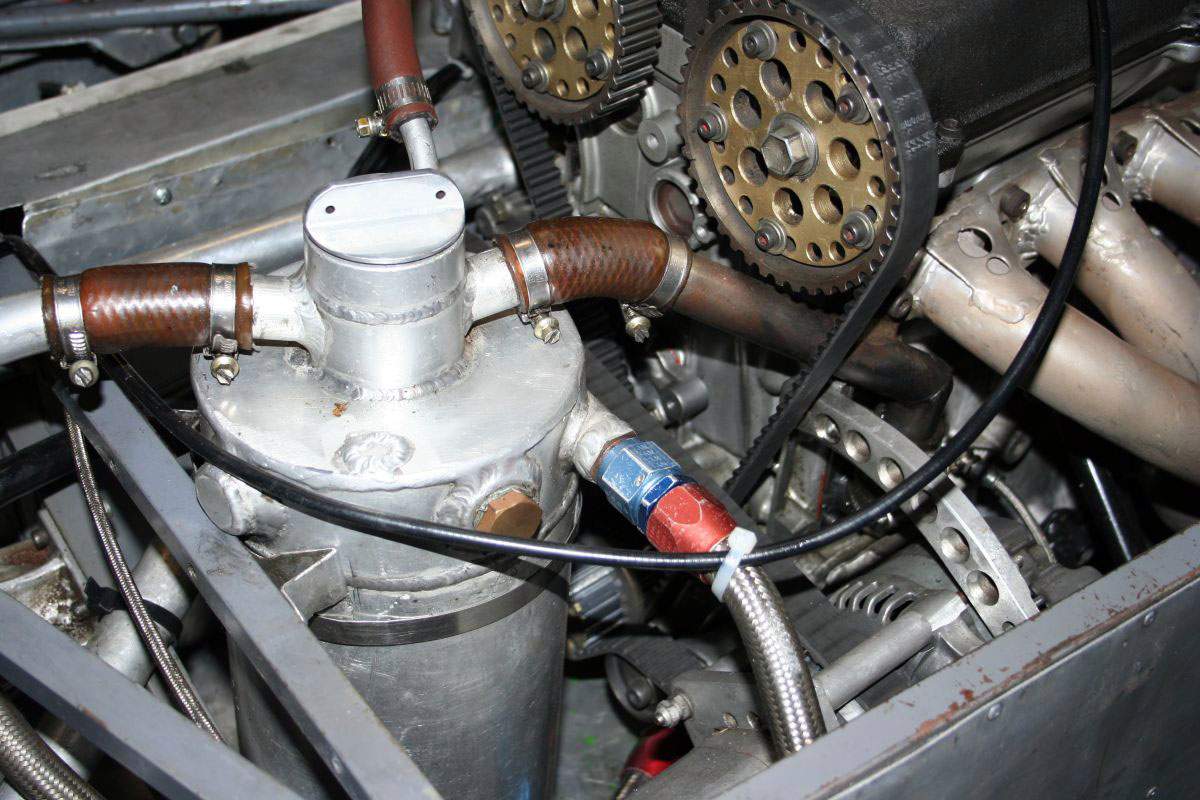

#3 is the oil return from the scavenge pump. It comes in tangentially, to spin the oil around the inside of the tank to help de-airate it. Also cross-section 'A'.

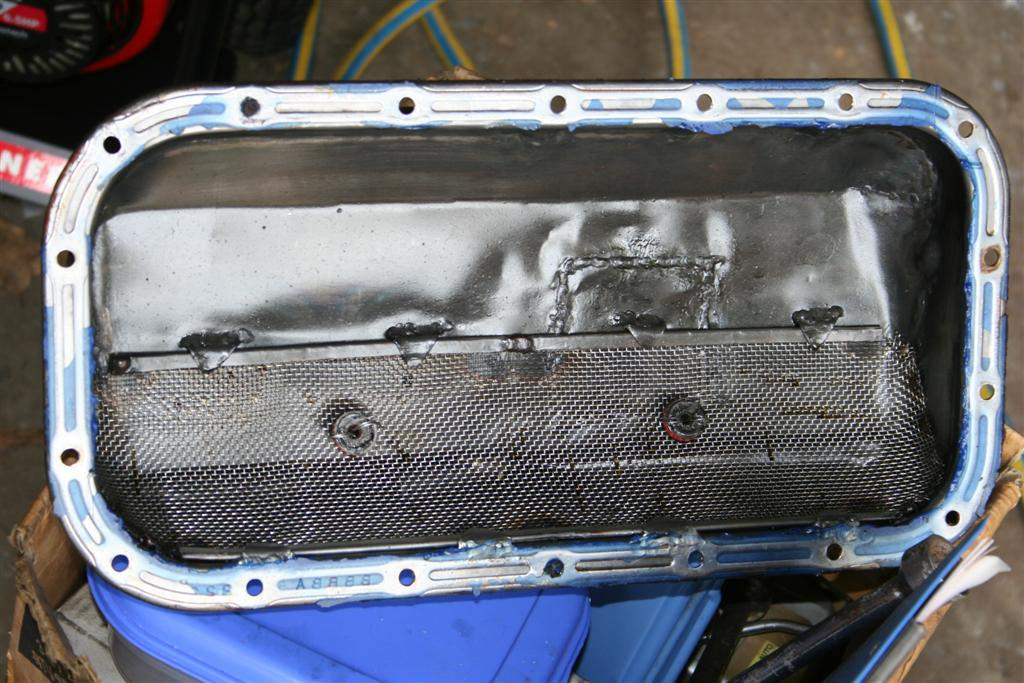

#4 is the plate that helps stop the oil swirling and fall down into the lower half. Also cross-section 'B'. Note the large hole in the centre, and smaller holes around the sides. It's also coned a little though this isn't too important.

#5 is the oil line to the pressure pump.

The oil level with the engine off should sit about 25mm below the plate. That level should be checked not long after the engine has stopped, as quite often oil will sneak back through the scavenge pump into the sump, so leaving the oil tank looking drier than it really is.

There's no real minimum oil quantity with an oil tank, as long as is never comes close to running dry at high revs and there's enough running around for the oil cooler to work on. If the oil cooler isn't working well enough, no matter how much oil you have it'll eventually heat up too much.

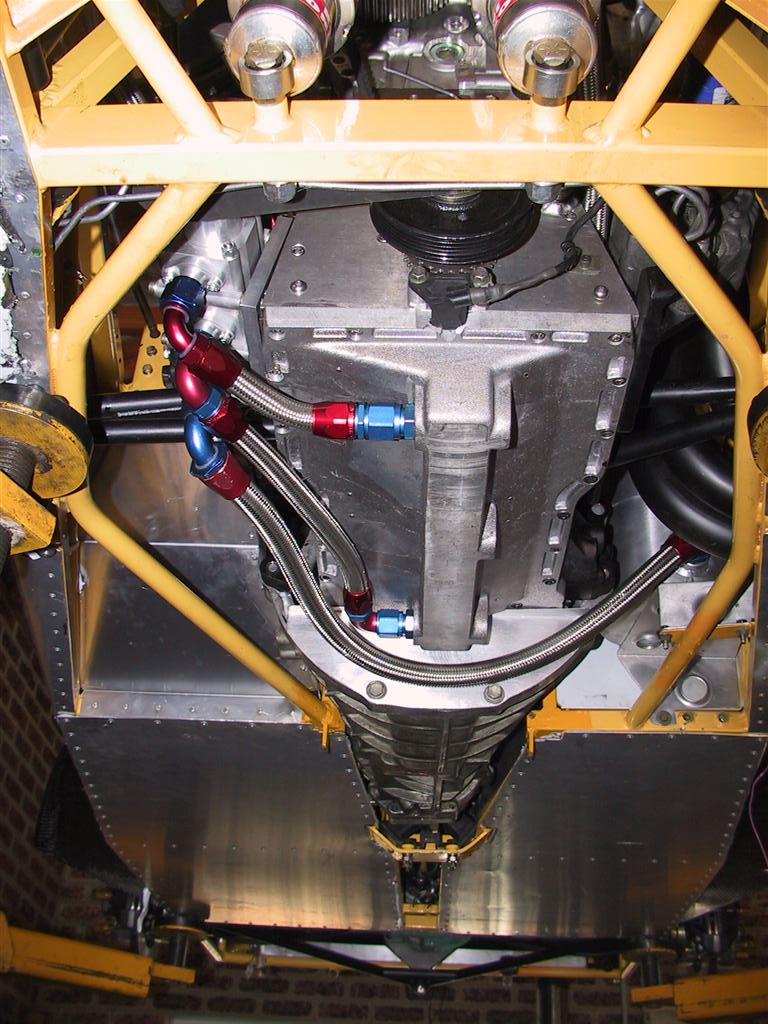

The really clever systems have the entire tank sitting inside the bell housing! But they're a lot harder to maching and keep cool.

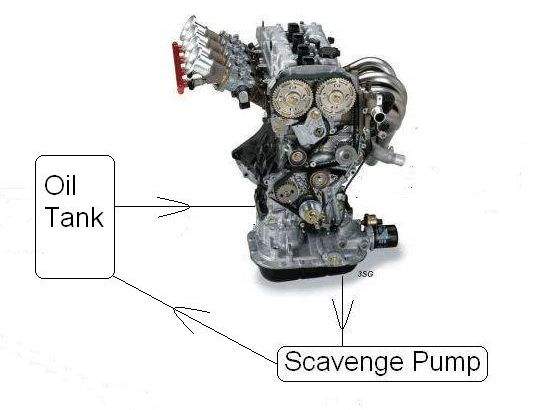

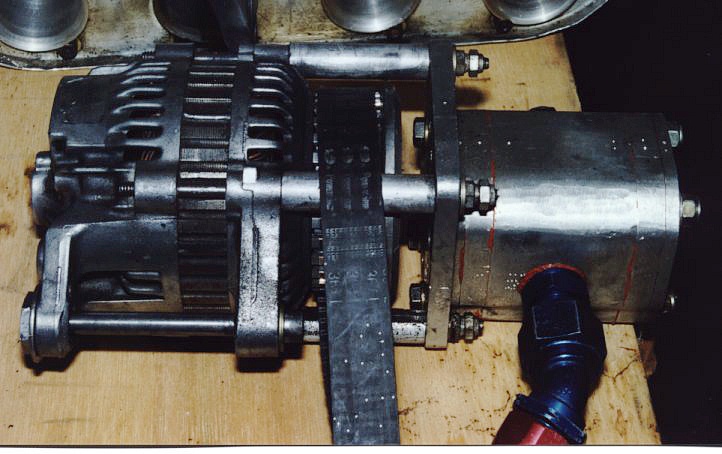

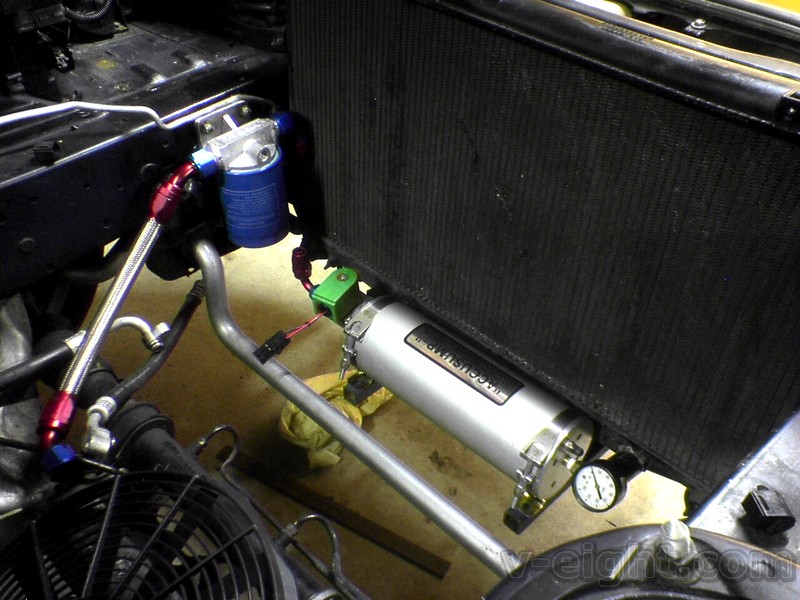

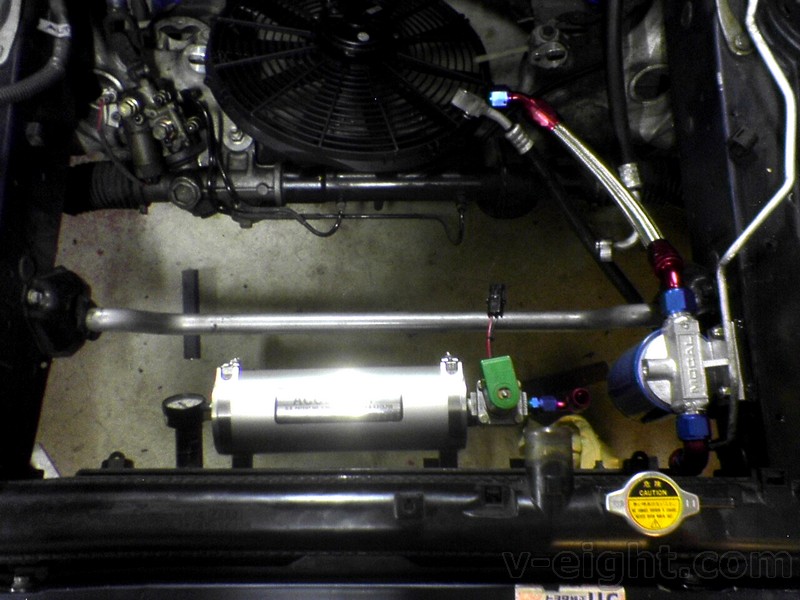

Here's another photo of my racing car engine, and it's got a few things that aren't right.

It's got a breather from the crankcase to the oil tank, and another from the cam cover. Those aren't needed, as the scavenge pump does all the breathing. On the new engine I'm building, it'll have a valve in the cam cover that maintains a preset vacuum in the engine. It's best to let the air in from the top, as the air will then travel from the top of the engine to the bottom, which helps the oil return from the head to the sump. The vacuum will be so good that for the twin-cam type engines that have the small semicircular rubber plugs in the back of the head, they have to be turned around so that the lip on one side is on the outside, or they will be sucked into the head.

Back to cooling the oil for a moment - A water-to-oil intercooler is a good thing for road cars and cars that only run for short-ish periods on the track. However, if the cooler is a good one (Setrab in-line type, etc) then they should be more than enough to do the job longer term. They also have the benefit of getting the oil warmer faster after startup, which helps reduce engine wear. The downside is that the water radiator must be able to shed the extra heat that has been added to it.

If in doubt, a conventional air-type oil cooler will be fine, but make sure it get good airflow through it.

That's all I can think of right now, more later maybe.

Hope this is of interest.

Reply With Quote

Reply With Quote

OMG... thanks billz... i was always wanted to build a dry sump for my 3SG...

OMG... thanks billz... i was always wanted to build a dry sump for my 3SG...

)..........however this could also help your engine bay space issue should you eventually decide to go for full dry sump system.

)..........however this could also help your engine bay space issue should you eventually decide to go for full dry sump system.

Bookmarks