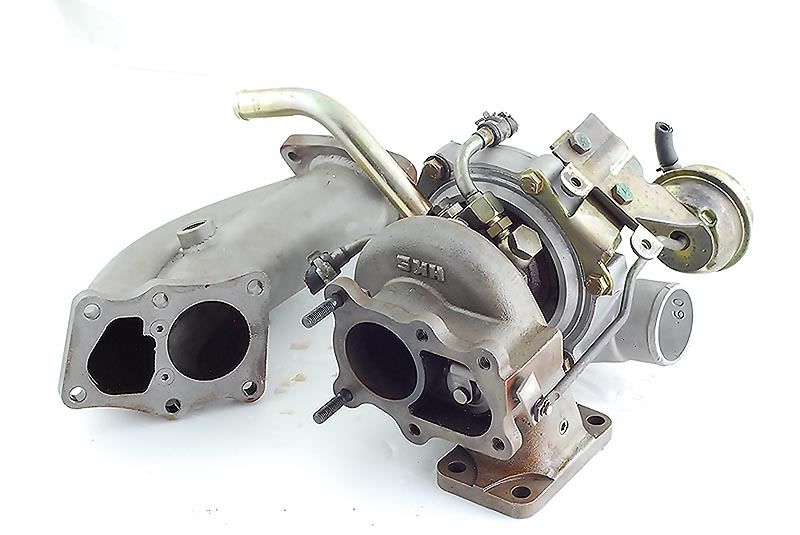

A divorced dump is designed to separate the two different exhaust gas flows - which is all aimed to improve response.

The outlet from the turbine is spinning because of the turbine, which isnt good for flow. The best case would be to 'promote' the spin to change to laminar flow which is apparently done by a sharp step up in pipe diameter (say from 2.5 to 3 inch).

The wastegate pipe is not used often (stays cool) and when it does it heats up rapidly compared to the normal exhaust, so if there is no flex in there then you may get some cracking. The length required before merging should be as long as possible (though there will be a point of no more gains but this can only be found by testing), but the drawbacks to this are space, weight and the previously mentioned thermal shock. And remember to increase the pipe diameter at the merge as you will have an increased exhaust gas volume and trying to put that throught the same diameter pipe will cause a restriction.

Also, if you are building this yourself then you have the opportunity to create a removable section for the track to make it a screamer pipe.

If you really want to know the difference, then hook up a data logger and do it the easy way first and make the changes later.

Reply With Quote

Reply With Quote ) sorry. No offense whatsoever taken.

) sorry. No offense whatsoever taken.

Bookmarks