as ive said before,

id be suprised if a slip yoke on a spline can actually move while the car is under hard acceleration. bear in mind that the engine would move the most under hard accel.

similar to a socket on a bolt i guess, while your exerting torque its hard to slide the socket over the nut head.

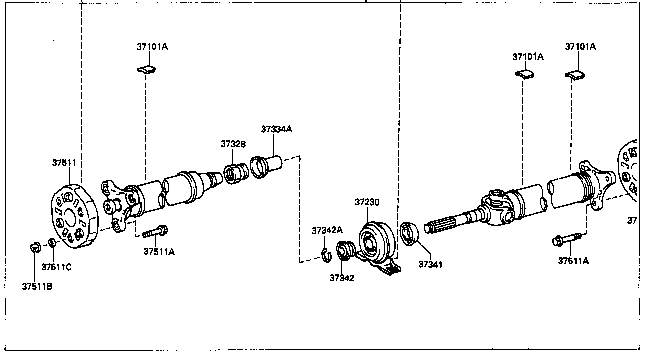

FYI im running a tailshaft with a fixed length and no slip yoke

Reply With Quote

Reply With Quote

), but it still doesn't tell me how much movement there is and hence how much possible stress that places on the rubber section of the 3 pronged part if there is not slip joint!

), but it still doesn't tell me how much movement there is and hence how much possible stress that places on the rubber section of the 3 pronged part if there is not slip joint!

Bookmarks