Sure mate, hope you like reading

Lets start from the start. The whole point of this whole build is to increase the rod to stroke (r/s) ratio of the 4A engine to something more suitable to a performance engine. For those that don't really know what r/s ratio means or why it's important, here's a little crash course :

Measuring r/s ratio is really easy, you take the rod's center to center measurement and divide it by the stroke of the engine. In the case of the 4A : 122/77 = 1.58:1. Engines don't tipically have ratio under 1.5:1 mainly for clearance reasons, piston skirt needs to clear the crank counter weight so the rod cannot be too short and because that ratio really changes the way engine behave. That is also why when toyota went and created a stroked version of the 4A, the 7A, they had to increase the height of the block to be able to increase the rod length to suit the longer stroke. The 7A uses 131.5mm rods for it's 85.5mm stroke : 131.5/85.5 = 1.54:1, still a little above 1.5 but a litter lower than that of the 4A.

Now why do we want a higher r/s ratio? Well, in a reciprocating engine, the piston traveling in a linear direction needs to transmit there energy to a rotating crankshaft. The position of crankshaft in relation to the vertical plane follows a sine curve but since the pistons are not directly attached to the crank pin but via a connecting rod, the piston position in relation to the vertical in not following a true sine curve but a modified one. You see, the highest vertical speed of the crank pin arrives exactly when the crank is at 90° to the axis of the pistons (90° and 270° at the crank), but when it is there, the rod is forming an angle since the crank pin is offset on the side by half the stroke of the engine (the length of the crank throw). So maximum piston speed doesn't happen there, but when the crank pin are positioned to have the rod forming an angle of 90° to the crank direction of rotation. Since the pistons are positioned on one side of the crank, that position happen a little before reaching 90°, typically around 80° and is mirrored on the other side so around 280° instead of 270°.

That brings a problem. Pistons reach zero speed 2 times per cycle, at TDC and BDC if the max piston speed was happening at 90° and 270° that would leave the same number of degrees to accelerate and to decelerate while going up and down the bore but since it happens when the crank pin are angled a little bit toward TDC, pistons will have to accelerate fater from TDC to max speed and have more time to decelerate toward BDC and then will accelerate toward max speed in 100° and have only 80° to decelerate toward TDC.

What that leads to is that acceleration forces at TDC are always higher than what they are at BDC. It also causes the piston dwell time at TDC to be lower than the piston dwell time at BDC.

But what does r/s ratio have to do with all of this. Well, the longer the rod, the less angle the rod will see on a complete cycle, thus attaining maximum speed closer to that 90°, reducing TDC acceleration and increasing piston dwell time at TDC while doing the opposite at BDC. According to what we saw, TDC acceleration will always be higher and dwell time lower than BDC so getting a longer rod will push the piston to follow a "truer" sine curve.

Lower acceleration at TDC will mean that strain on the rods will be lower, allowing either more cylinder pressure or allowing to rev higher before the engine will longer rod sees the same abuse than the same engine with shorter rods.

But it doesn't stop there, the rod angle is also of prime importance in a performance engine. When ignition occures in an engine and piston passes TDC, the whole force of the piston presses on the rod and to transmit its energy to the crank shaft but while the piston moves down the bore, rod angle also increase. At that time, the piston is still traveling down but the force is transmitted at the angle of the rod. If you've done really basic physics in school, you'll know that when a force is applied at an angle, it is actually split in to, a portion of the piston force is pushing down the rods and an other portion is transmitted at the same angle on the other side, trying to dig the piston in the side of the bore, increasing friction which is HP killer and is also bad for durability, both cylinder, ring and piston durability. Since higher cylinder pressure happens after ignition and the engine rotates only in a single direction, the side forces created by rod angle are highest on one side of the cylinder bore : the major thrust side. Now in a 4AG engine, with the engine rotation clockwise, the major thrust side in on the intake side... if you know your 4AG well, you'll know that the early ones had 3rib and the casting was later changed to a 7rib design. Where are those 4 extra ribs? Yep, right in the middle of all 4 cylinder bores on the intake side... coincidence? I think not

And if you think those forces in an engine are low, I calculated the G forces in a standard 4A to be upwards of 3000 @ 7700rpm... that means that the 1lbs piston is exercing a force of over 3000lbs, much more than what the car weight and we are talking about forces if you just spun the engine with no spark plug in... now start compressing stuff and igniting fuel in there and you can relly appreciate the forces that are sent on the crank shaft.

To prove my point even more that a higher r/s ratio in a 4A engine is desirable, when it was time to create the ultimate 4A, the atlantic, they had to cas new pistons with the piston pin moved higher up in order to use longer rods to get a r/s ratio of 1.7:1 over the stock 1.58:1. If you look at a lot of engine design, you'll notice that the higher revving engines will typically have a higher r/s ratio. Bike have ratio above 2:1 while Formula 1 engine, that revs upwards of 18,000rpm, have higher than 2.5:1 r/s ratio.

With my recipe, you increase the rod length to 137.4mm while retaining the 77mm stroke to give a nice r/s ratio of 1.78:1 not F1 territory but way better than the stock one... not even talking about atlantic's one

What the higher r/s ratio give in real life above the lower accel speed (lower strain on the reciprocating parts) and lower side friction in the bore is also a higher resistance to ping with the higher TDC dwell time of the pistons by not having to advance ignition timing by as much as a "shorter rod" engine.

Unlukily it is not without downsides. The first one is mainly that you need a taller engine block, increasing weight (marginal in our situation) but pushed to the extreme it could make a notable difference and also you need to stuck the engine under the low bonnet of the car, once again in our case it doesn't make any difference but it could if pushed to the extreme.

Something else is that longer rod will weigh more. In my case, using the smaller 40mm crank enable to have smaller big end rods so I end up with a rod assembly that weigh a little less than the lightest 42mm rods, the blacktop ones. The downside is that the crank is likely less tough but by having less forces thrown to it via lower accelaration forces it might be sufficently strong. One good thing about the 40mm crank versus the 42mm one is that the smallest one is lighter and also the journal speed at the same RPM will be lower, decreasing friction loss once again.

Lower time at BDC will also decrease cylinder scavenging, which is also worst at lower engine rev so a long rod engine will need either bigger intake ports, a camshaft a little more aggressive or more lift and will therefore have it's torque curve pushed higher up the rev band. Luckily, it's higher resistance to ping should enable to use higher compression pistons which could negate this downside... not totally but still.

So now, a lot of guys have asked why not use the 7A internals and get a 11% increase in displacement. The 7A crank is poorly designed on the lubrification departement and even if you'd make a billet one with the right oil passage drilled and smaller rod journal, the geometry will render the 11% in displacement negligeable... could even end as a down grade. You see, the difference in pistons peeks acceleration between the 7A and my recipe are exaclty 7%. What it means is that to have both engine on par concerning peek acceleration at TDC, you'd have to rev my engine 7% higher than a similar 7A... and since HP is :

Instantanious torque * RPM / a constant

the higher torque of the 11% bigger 7A will not equal in 11% increase HP if the 7A (and bear in mind that this is comparing same engines with only a difference in the bottom end geometry). Well, 11% more torque > 7% more rev : 7A win again? Well no necessarily... since the 7A is a 4A stroked, that 11% increase in displacement is all taken with a higher torque, increasing piston speed and with the poor r/s ratio creating higher friction load, the little advantage the 7A still has in increased torque is more than likely to be eaten all the way, even more by increased friction loss at higher RPM. And we are not even starting to get into the whole higher piston dwell time at TDC = less tendency to ping = better anytime of the day.

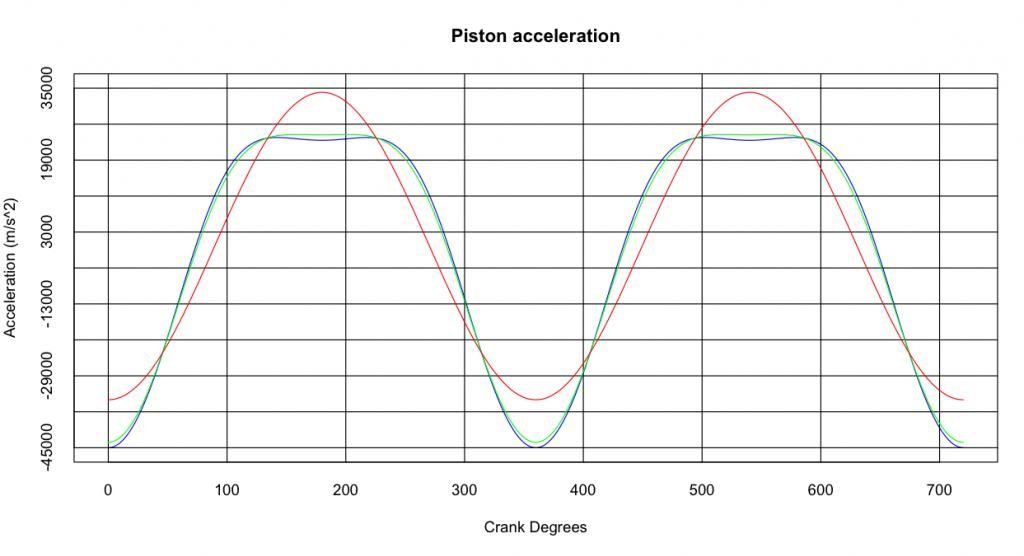

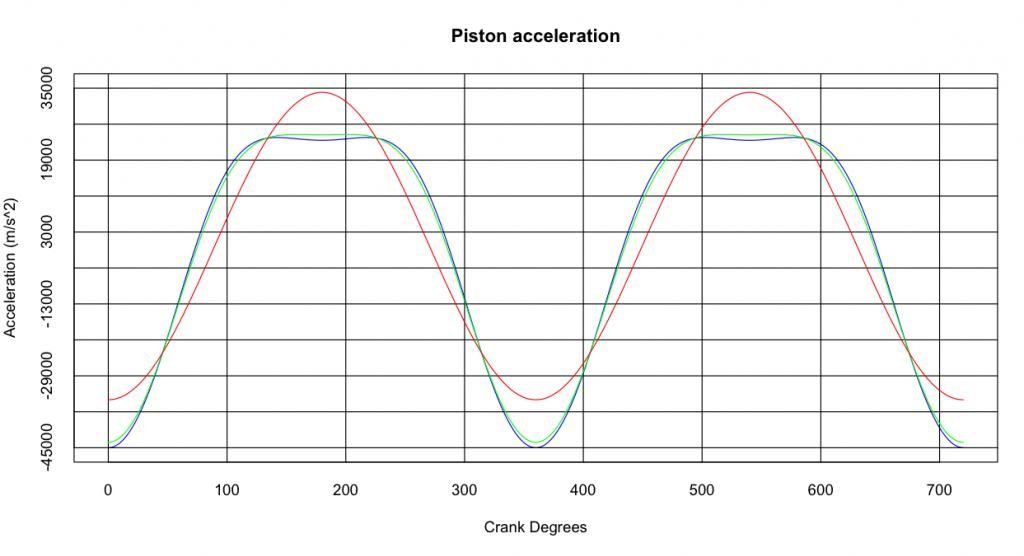

And to leave it there, here's a couple graphs I made :

First is the difference between stock 4A, tom-age and the same engine with 77mm stroke but a 10m long rod (do not attempt, it's just to ilustrate an the point of what happens when you increase rod length. Notice the "y" axis on the acceleration graph

Red = 10m long rod

Blue = 4A

Green = Tom-AGE

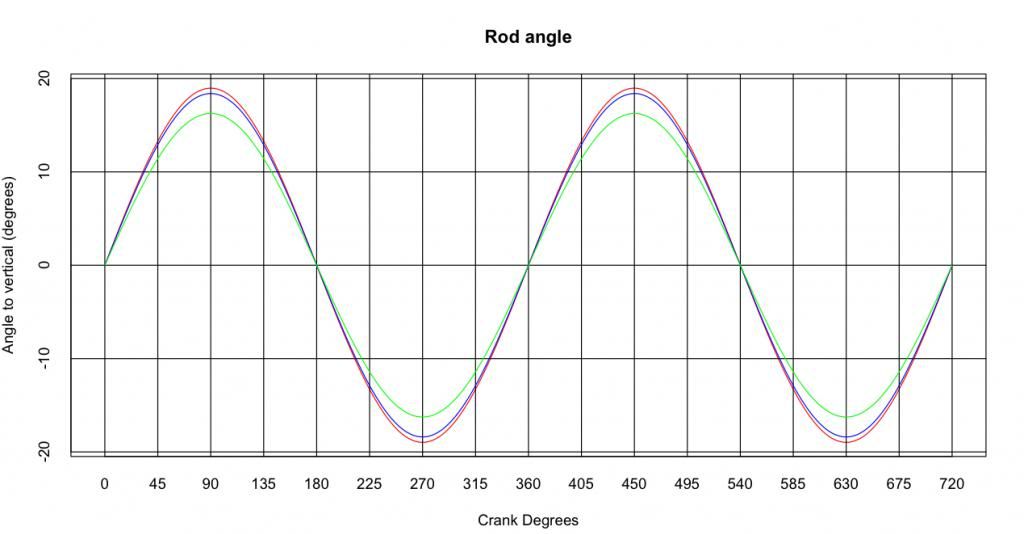

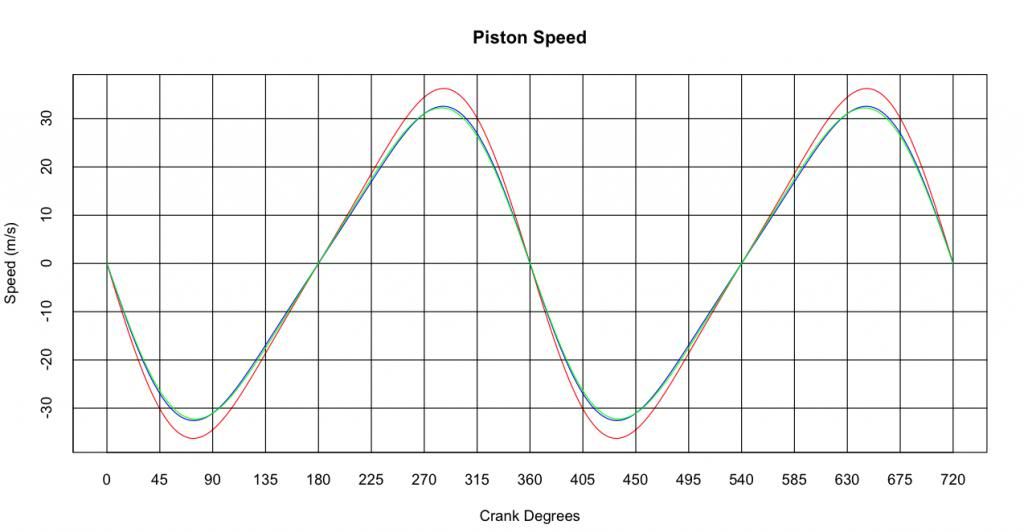

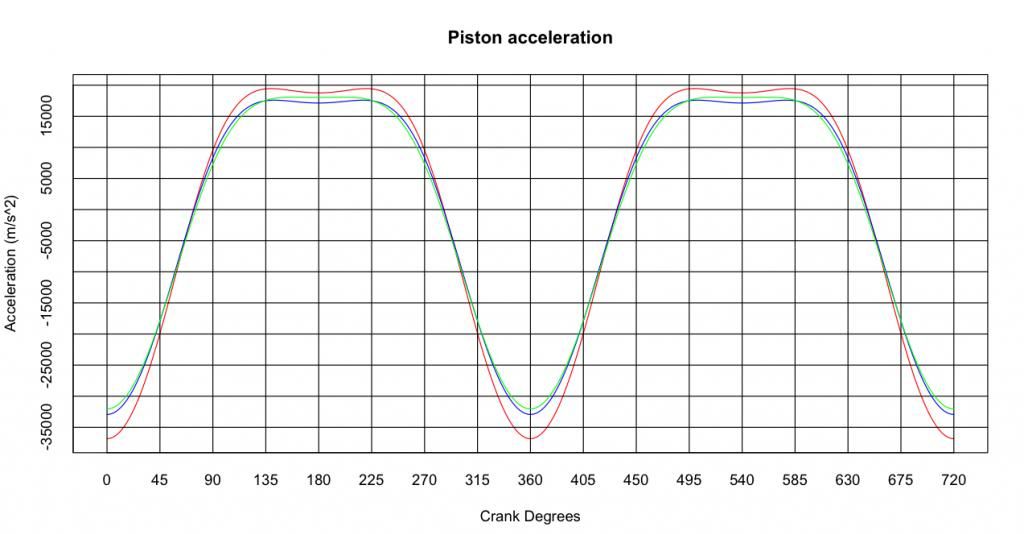

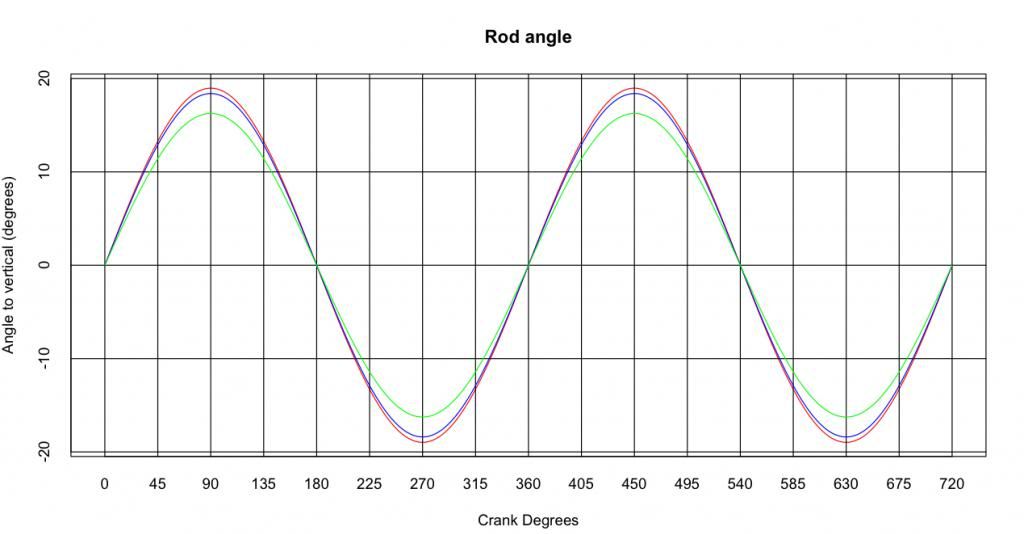

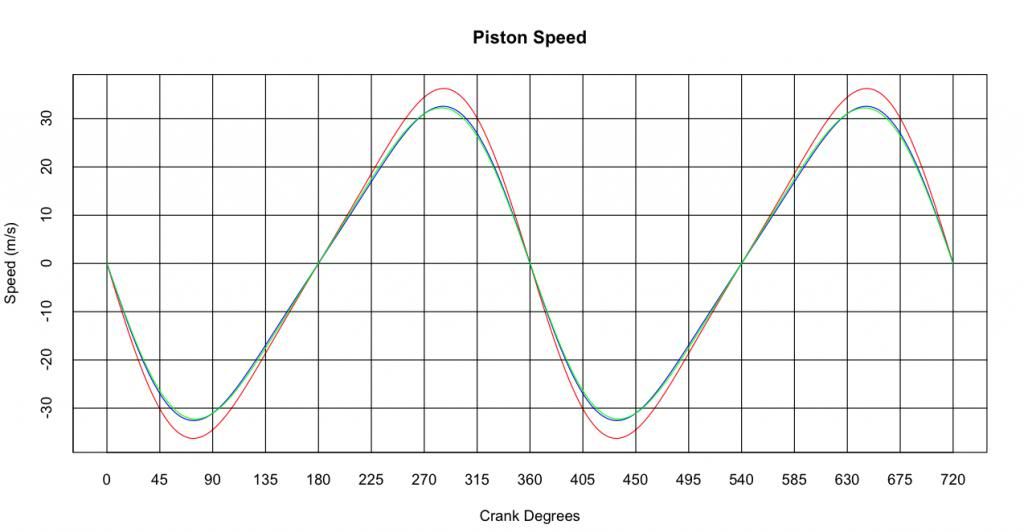

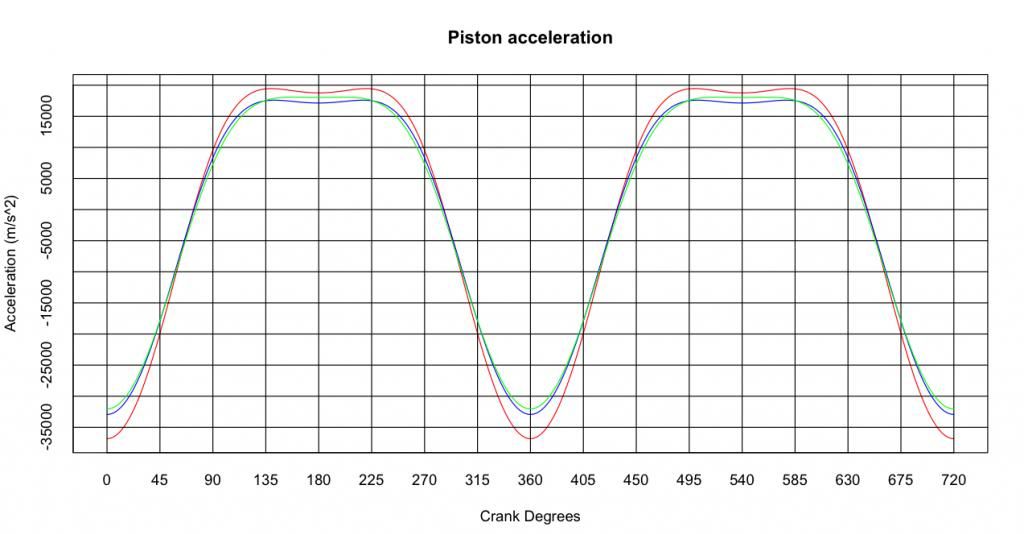

Here is the same graphs with 7A, 4A and tom-age

Red = 7A

Blue = 4A

Green = Tom-AGE

End of lesson... but I won't go too far away if anyone has questions

->

->

Reply With Quote

Reply With Quote

Bookmarks