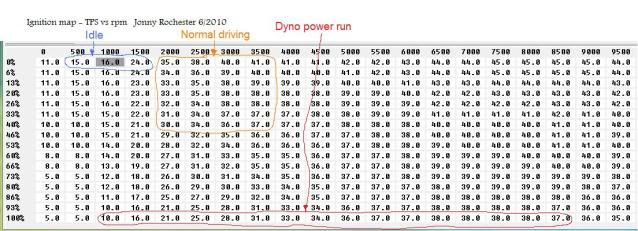

I often use timing around the idle speed to control the idle speed, for example if you want it to idle at say 800rpm, and ignition timing is say 10deg, below 800rpm you start ramping the timing UP, and above 800 rpm bring it down, it keeps the idle REALLY stable, use idle speed control valve to control any additional loads. If done right, you can have your electrical loads come in while the rpm still stays low and the engine just purrs away.

A dyno power run doesn't touch that part, correct, but steady state load test does, this is where you tune MTBT and optimise it, hold it at say 3000rpm and alter your throttle angle whislt optimising torque, I did this a few weeks ago with a group of people on a 2.6ltr turbo gemi and they were astounded at the monumental leaps in torque as timing was optimised at load points.

Reply With Quote

Reply With Quote

Bookmarks