Before I start getting technical, wheel and tyre dimensions can be confusing as no matter where you are in the world, you will see the dimensions are referenced in both metric and imperial and at the same time.

A good example is the 185/65/15 on your tyres, the 185 refers to the tyre tread width is mm, the 65 is the % ratio of the wall height and the 15 is the rim size in inches.

Some performance tyres can be 240/580/15, simply this is 240mm tread width, 580 rolling diameter and 15” rim diameter. Confused now??

So let’s start with;

Rim Diameter

Rim Diameter is determined by the overall diameter that the tyre bead is fitted to. This can quickly be identified by the tyre size 185/65/15 where the 15 tells you it is 15” (inches), if you don’t have tyres, measure the overall diameter across the rim where the tyre bead seals. Do not measure the overall rim diameter size from outer edge to edge.

Rim Width

Rim width is determined by the maximum width where the tyre bead is fitted and seals between the two outer lips. All rims have an outer edge for the tyre to seal against, this can be rolled metal or thick cast alloy which can be as much as 12mm on each side. Do not measure the overall rim width from outer edge to edge.

PCD

PCD stands for Pitch Circle Diameter. This circle is determined by the positions of the bolts/studs. The centre of every bolt hole lies in the circumference of the PCD. The PCD was once in time always in imperial inches, but now more common in millimetres. The most common PCD’s or circle diameters are 98mm, 100, 108 (4 ¼”), 114.3 (4 1/2”), 120 and 130mm’s.

PCD also needs reference to the number of bolt/studs used for a particular purpose. Most common is 4, 5 & 6 in modern cars. You will see this as 4x114.3 or 4/100 and other variations.

It is easy to determine the PCD on 4 or 6 stud wheels, this is merely the distance between the centres of two of the holes directly opposite each other.

For 5 stud, this requires some maths. Measure the distance between the centre of two adjacent holes and multiply by 1.701. In the case of a 5 stud rim, the distance between two adjacent holes is 67.2mm, multiply this by 1.701 and you get 114.3. Who said you don’t need an edjumaction!!!

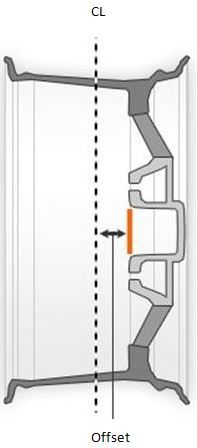

Offset

The offset is simply the distance between the centreline of the wheel and the hub face that mounts to the cars axle, this can be either positive or negative. Offset has a significant effect on many elements of the cars suspension, including suspension geometry, clearance between the tyre and the suspension components, the scrub radius of the steering and the track.

Most modern cars have a positive offset as new technology and theories prove that there is more responsive steering and less load on suspension and axles.

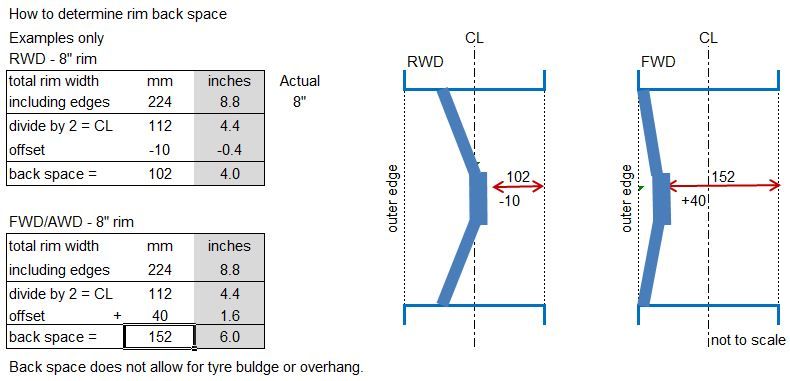

Back space

Usually, you won’t find backspace referred to in wheel sizes. But I find it useful to know how much clearance you have from the hub face to the inner rim edge plus allowing for tyre buldge.

Clearance to struts, spring mounts, lower control arms when roll centre adjusters are used and other suspension parts all need good clearance while at the same time getting as much rim and tyre inboard is good for geometry and scrub radius which will reduce understeer. Hence why most modern cars have negative offset.

The reason why I like to get the inner edge inboard is to get the widest rims/tyres in under the guards, but that’s just me.

Centre bore

Simply the centre bore is the hole in the middle of the rim. The size of the hole is determined by the hub or axle of the vehicle for which the rim is intended. The important rule is that the centre bore must always match the hub or axle locating ring.

Oversize centre bores can and will cause undue stress on wheel nuts and studs. This will also impact rim run-out and cause imbalance and wheel wobble. On the reverse, being too small will prevent the rim from sitting on the hub/axle locating ring and will cause severe wobbles and fatigue of all parts and impossible to drive.

Feel free to add your comments, corrections and experiences

Reply With Quote

Reply With Quote

Bookmarks