You would be best installing a pump to keep the system pumping through and return into the sump...maybe even make it a complete independant system...(or go dry sump)

Car. AW11

Engine. 4AGTE

Problem. Inadequate oil cooling

With the crapass packaging that is the AW11, it is near impossible to have a decent oil cooling solution. One method I am considering is to run lines up to the front of the car and run the oil cooler up the front like a normal car, where the cooler will get a nice faceful of fresh air. The only thing is I am worried about the length of the lines (they will be somewhere around 6-7metres all up) and whether they will cause pumping issues for the oil system.

Even with my current rear mounted setup the car still has some 3-4 odd metres of oil lines and pressure seems to be unchanged to when there was no oil cooler on board, but if I could get some better educated opinions that would be good.

Cheers.

Vito.

You would be best installing a pump to keep the system pumping through and return into the sump...maybe even make it a complete independant system...(or go dry sump)

Could you fit a water cooler block ub the engine bay so any long lines have coolant instead of oil? See Bill Sherwood's racecar for tiny example.

brendan had a water to oil cooler on his and it was useless. i dont think a water to oil setup would work unless i go for a megabucks laminova core. and tbh i want less hoses in my engine bay if i can help it.

can you mount it under the car somewhere rather than go all the way up the front?

or in the rear bar or something? both of those should give good airflow without massive lines

never looked at an adub up close just some ideas....

There is no substitute for PUBIC inches

Never late in an x8

W2O cooler should give you more consistent temps (and quicker warmup of oil). Doesn't have to be stupidly expensive but size and flow need some consideration.

You could mount the cooler in the boot out of harms way?

Bill's cooler was this

tho I think he changed it to a Subaru (?) W2O cooler. I think his build thread here or on PF has more info.

edit: found build thread on PF, yes it's not a 4A donk, but it's race proven.

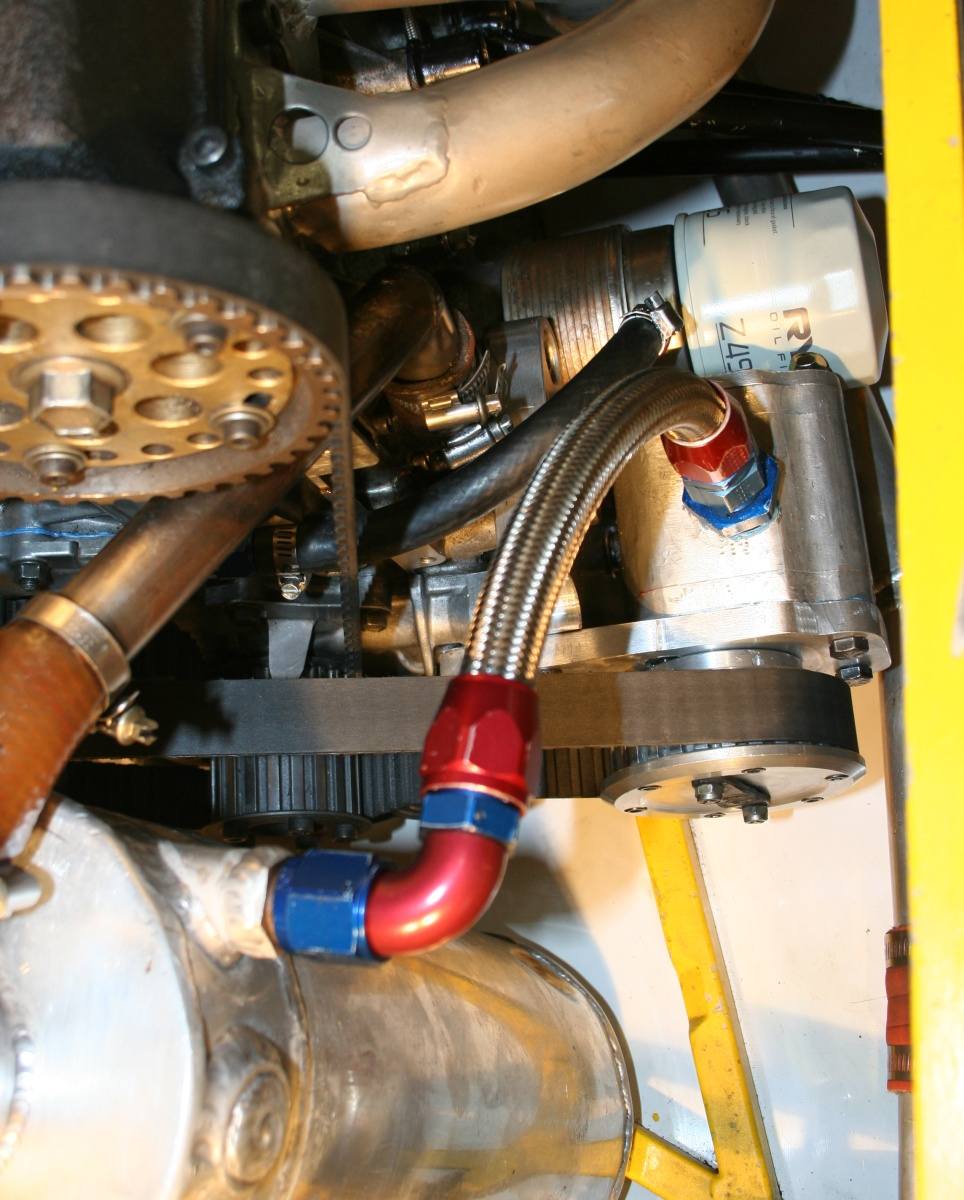

Current cooler is from a Subaru, is a donut cooler mounted between filter and block. Engine runs a scavenge pump for the dry sump but feeds the collected oil direct to the factory oil pump.

Last edited by thechuckster; 17-01-2012 at 12:28 PM.

Currently have an FD rx7 oil cooler mounted under my rear bar. you would think it would work OK there but it doesnt. I saw 130deg oil temps on just three half speed laps at wakefield park last week. The other thing is that my setup is turbocharged of course so you get a LOT more heat being put into the oil system as the oil flows through the turbo....

Bill's setup works well no doubt, and if I have to resort to a water to oil cooler then so be it, but for now I just want to know whether it's possible to run lines that long and use an air to air cooler.

Been doing some searches online for some rules of thumb (could calculate the pressure drop myself but might miss some stuff and make a booboo) and found this

http://images.thesamba.com/vw/gallery/pix/269226.jpg

Pity it's in imperial. does anyone know the flow rate of the stock pump?

Are sure the current location is good for air-flow? thought about boot mounted with a forward-facing scoop (or NACA duct) feeding it air coming over the boot, ducting covering the cooler then hot air exiting out the back of the car (Audi quattro group B style)?

i know about all these options (and others), for the moment i would just like an answer to my original question

did some searching, apparently AE101 GZE and silvertops have a higher spec oil pump.

A winner:

(linky)For what it's worth, I've been told that a 4AGE pump delivers 45 litres/minute at 8000rpm or thereabouts.

and

(later down same thread)The capacity is the total flow out of the pump. The actual flow through the engine would be that less the (unknown and variable) quantity that is passed straight back to the sump through the relief valve

Bill's suggestions in several threads was to take any sharp edges out of the oil flow paths in/out of the pump.

And partly related, some hachi-nerd has done some measuring of shim thicknesses with reference to oil-pressure. Superhachi.com - Compressor Map Tutorial

u could always make it over complicated by using a water-to-oil cooler, but instead of passing engine coolant through it, have a seperate coolant system just for the oil cooler? small front mounted radiator, a pump, and a temperature switch to turn the pump on once the oil is above a certain temp?

SHEPPO..

thankyou sir although the pressure drop at high revs is likely not to be an issue as the bigger problem at revs is oil not draining back fast enough to the head. the fat that the pump has a rpessure relief valve built in indicates that the pump is able to cope with higher pressure requirements with some revs on board. the bigger issue i forsee is at idle where pressures are quite low, but being a positive displacement pump it shouldnt be an issue i dont think.

that's the thing, *should/shouldnt* and *i think* is what i am trying to replace with *will/will not* and *i know*. as i'd hate to take a gamble like this on what i *think* might be ok

ever checked to see what egt are ? could be running rich or/and retarded on full boost and getting warmer than it should ?

i would have thought you could setup an under car pretty efficiently. could you mount it where the side vent is ?

i dont have a funny or cool signature.

Mount oil cooler in side vent, mount 8" Spal fan on it.

Seen this done on a couple of AW11's now and it seems to work well for them.

Bookmarks