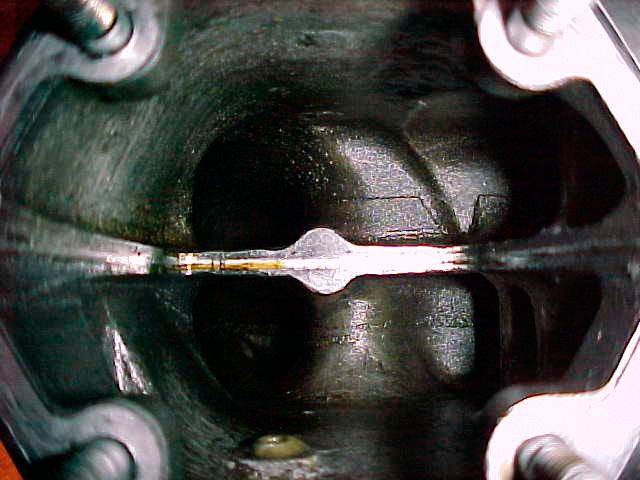

This is actually quite debatable. But more in real world application rather than modelling. When you have a plate blended into the end of the mouth you can get a higher flow than say if the radiused mouth was suspended above the plate like so:Originally Posted by Earlyrolla

http://www.billzilla.org/inman.jpg (thanks Bill for the pic)

However, in the real world, and especially on NA engines where the maximum amount of air needed by the engine doesnt max out the flow rate of the throttle/runner assembly the protruding style seems to be more effective as it promotes a higher airspeed through the center due to the reduction of the width of the eddies on the edge of the runner. This is quite important in NA engine design.

But for FI where you are effectively ramming more air into the throttle than it can theoretically handle, the absolute maximum flow rate does play a part and therefore having the stacks blended into the runners serves as an advantage.

Ill try and post more after i go out for my 9k walk this morning

Reply With Quote

Reply With Quote

Bookmarks