pull rotating section out of both dizzis and swap the trigger wheels?

I have been stewing on this for a while now

My pride and joy is sitting there just waiting to get out of that garage.

I'm building a 5s-ge, its ready to go, all is left is this distributor to sort out.

5sfe distributor shaft does not fit in the head, only the 3sge one fits snug. However, the sensors inside are different.

The 5sfe has one pick up sensor, and a cog with 4 teeth

The 3sge has 2 pick up sensors, and a cog with 1 tooth.

In desperation, I initially plugged up the 3sge distributor, ignoring G2 pickup sensor and just running with G1 to attempt to mimic the single pickup in the 5sfe (while being stupidly ignorant to the teeth on the cog) and, car didn't run smooth at all, was backfiring and spitting and everything, regardless if i retarded it heaps, or advanced it heaps. AND CRAZY OF ALL, although the coolant temperature was normal, the exhaust manifold became red glowing hot!. Not good.

So....

I chopped up and modded a 5sfe distributor to have a longer shaft to sit in the 3sge head, along with a longer hold down bolt . At first trial it worked perfect. car ran like a dream. 2nd go, it fell to bits. Taking into consideration the engine was only doing 3000rpm, that means the dissy was spinning at 50 times per second and the non' professionally machined and non-professionally balanced stuff just fell apart. The modded 5sfe distributor just didn't sit right anyways.

So i'm looking into some form of electronic manipulation instead of mechanical. what can i do? if i change to a 1986 ecu than it won't work with my set of guages inside, and will have to change all my other sensors and the loom.

I just wanna plug a flush seated distributor (like the 3sge one) with the right signals going to the ecu. The guts just can't be removed from the 5sfe and bolted into the 3sge without having to hack it up.

IF worst comes to worst, what kinda workshop would be best to help solve this problem?

st185 GT4 309 hp 12.4s 1/4 mile 16psi

pull rotating section out of both dizzis and swap the trigger wheels?

I was thinking of a toyota ESA type dissy. Chris

Last edited by Chrisso; 08-12-2008 at 03:45 PM. Reason: completely wrong, the drugs were working well this day.

AE86 4 shades of silver - The Lone Ranger's steed is on the road again!

AE86 shell - waiting for a donor car from the auctions.

To rehash - you have a 5S-FE 4 tooth 1 pickup dissy, and a 3S-GE 1 tooth 2 pickup dissy, and you're trying to make it work with the 5S-FE ECU, right?

The 3S-GE dissy has 1 tooth, so there's nothing to cut.

If the 5S dissy is smaller and longer than the 3S-GE dissy, you should be able to get a collar machined to go around the 5S dissy. If the shaft is too long, you could make a plate up that sits between the back of the head and the dissy, with longer bolts. (I might've got this completely wrong thoPictures help

).

Why are you choosing a 5S-FE ECU over a 3S-GE ECU with larger injectors or "adjusted" AFM? I haven't put a lot of thought into a 5S-GE but applying the thought process of a 7A-GE I would've expected the GE ECU with larger injectors would be the better approach - ie the head is the more critical component. Is the 5S AFM or Map? If Map, I would think that it would not be appropriate given the VE of the engine is largly dictated by the head. An AFM ecu would be expected to mostly compensate for the different head.

Gauges should not be affected by choice of ECU at all. They usually run off different sensors - it's not until 98-99 models that gauges started running off networks. You'd need to change the sensors for the ECU only, not for the cluster. Is this an ST184?

In terms of electronic manipulation, creating 4 signals out of 1 (or 2) is possible but afaik no one offers something to do it off the shelf. I would suggest you would be better off using an aftermarket computer than to pay to have an electronic solution made for you.

In terms of mechanical solution, is there any reason (other than actually doing it) that the 5S rotor couldn't be pressed onto the 3S shaft?

Mos.

Admin, I.T., Founding Member, Toymods Car Club Inc.

2000 IS200 Sports Luxury 1UZ-FE VVTi, 1991 MX83 Grande 2JZ-GTE (sold)

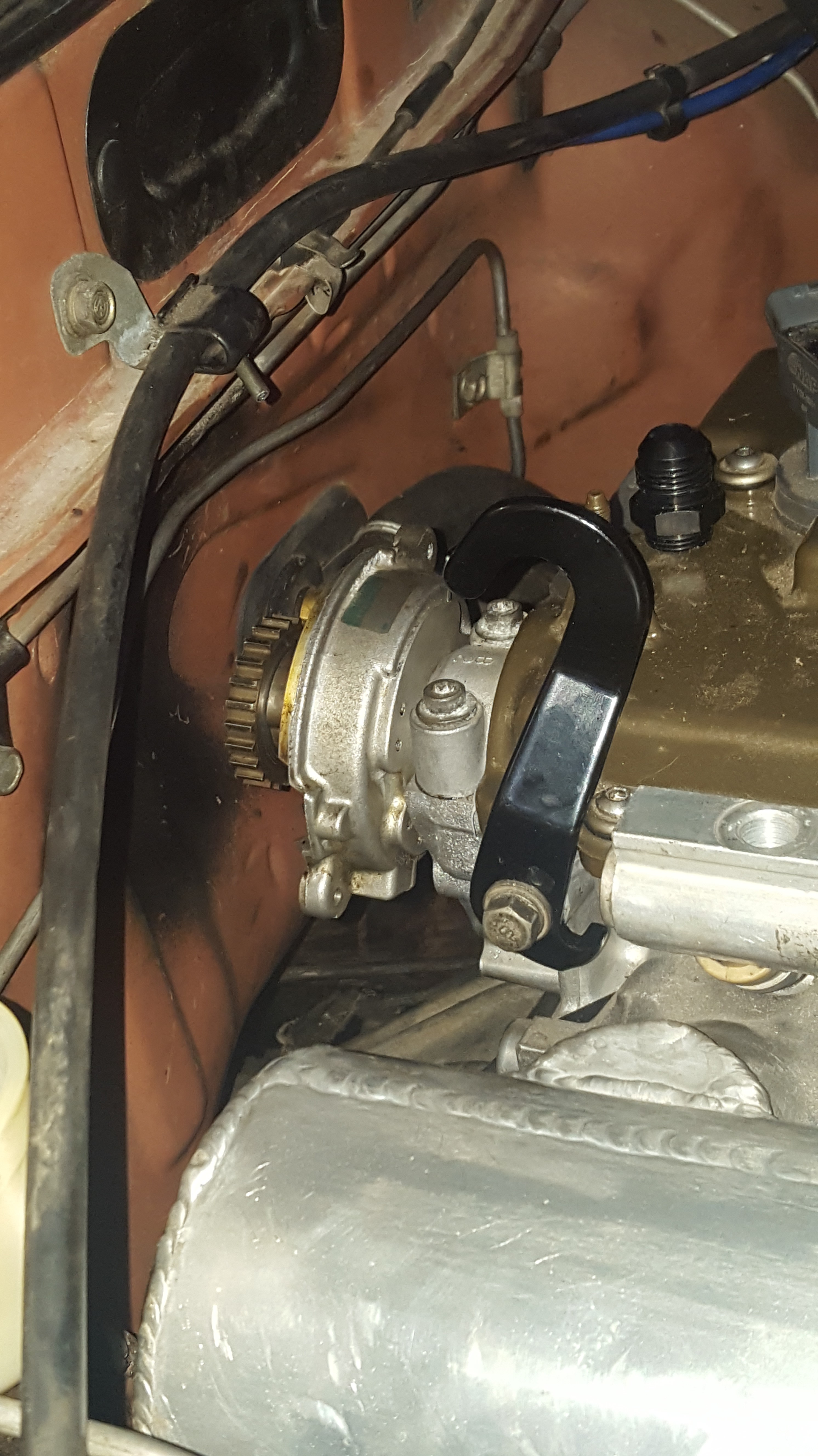

Im modifying a 5s dissy with st162 3sge dissy internals. I just want a little more firewall clearance. It is going to require some machining but hopefully by this arvo I'll have some pics of how I've done it

Cheers, Peter

My Rides:

1x Brown St141 corona csx. powered by a gen 2 3sge, 1x RT142 turbo 1UZ, cd009 and G series, 1x Gj Sigma Scorpion injected and turbo'd, 1x KE30 2TG, w58 and F truetrac, 1x RT104 18RG, w58 and F truetrac

so, a bit of a win and a bit of a lose, machined the trigger wheel off the 5s shaft, machined the 3s shaft off the trigger wheel, added 2 grub screws and affixed it toi the 5s shaft, then I machined the 5s dissy housing down to the 3s diameter. If i had stopped there i would have been golden but no! I wanted to run the 3s o ring on the housing shaft, started cutting oring groove and parted the end of the housing off. made a press fit piece of ally to go behind the bearing and pressed it in, then i ran out of time. need to find a seal smaller in od than the 3s/5s one and machine a seat into the alloy then i can bang it all together and it shoud work a charm.

Clears the firewall a little better though

My Rides:

1x Brown St141 corona csx. powered by a gen 2 3sge, 1x RT142 turbo 1UZ, cd009 and G series, 1x Gj Sigma Scorpion injected and turbo'd, 1x KE30 2TG, w58 and F truetrac, 1x RT104 18RG, w58 and F truetrac

Very interesting. More room is always nice.

1990 ST185 Running stock Gen 3 power, 216awhp at 15psi. 13.6 second down the quarter

Bookmarks