Well it's almost bolt-on. 2 things need to be adressed

1) E16 rod small end is supposed to take a 19mm press in piston pin. 4A-GE piston either use 18mm press in or 20mm floating pins. The most cost effective thing to go is to get a machine shop to oversize the small end to use redtop or 20v piston with there respective 20mm pins. You could either bore the end, press a brass bushing, make an oil hole in the small end and use the 20mm pin as a floater like all late 4A-GE engine or just oversize the small end and leave 0.003" interference and press the 20mm pin which leaves more rod material around the small end and is also cheaper.

2) E16 rod bearing are a little too thick to use on a 4A crank since the crank pin is slightly undersize on the E16. 4A-GE small rod bearing (bluetop) fit the rod pretty well but the oil hole on the E16 rod is on the other side. In order to direct oil up under the piston, you can simply drill the bearing and chamfer the hole or make a "cosworth notch" on the side of the big end like the blacktop has. I decided to make the notch since the bearing already has a hole (that is now blind) I didn't want to reduce the bearing surface any further.

Here are the modded rods to fit

Bored small end to press the toyota brass bushing and drilled an oil hole. Now the setup is full floating and uses the stock 20mm floating piston pin that are on every late 4AG, smallport, 20v and GZE

Notch on the big end, 2mm wide, 1.5mm deep

Symmetrically on both sides for good piston cooling and pin lubrification

And all that is what's needed to turn this into a long rod 4AG

Final piston rod assembly, weighting in at 950.8g, compared to the 909g or the stock bluetop assembly and 920g or the 7A. The rods with ARP bolt weigh in at 482.2g, from what I was able to gather, blacktop rods weigh in at 485g.

Throw all that in a block...

And you end up with a destroked 7A-G or a bigblock 4A-G... or like a couple guys on a local forum started calling it, a Tom-AGE

So the parts list goes as follows

- 7A engine block

- 4A-GE bluetop small journal (40mm) crankshaft (early TRD crank with 40mm journal could also be used if such a thing can still be found and a 4A-FE crank would work but the 6 bolt flywheel and half weighted crank plus the crappy oil pass won't)

- 4 connecting rods form either a E16 or E15ET (very important not to use non-turbo E15 rods since they are longer)

- 4A-GE head of your choice, bigport, smallport, 20v

- Intake that goes with the head

- 4 pistons that goes with the head also. For all 16v head, use smallport highcomp piston (for the 20mm piston pin), for 20v head uses any 20v piston, for F/I use GZE piston.

- Any A engine crank bearing : 48mm crank journal are all the same

- 4A-GE bluetop small (40mm) rod bearing (4A-FE would work since they are the same)

- 7A or late 4A-GE oil pump (19036) found on the smallport and 20v engine. Both oil pump have the late sinus gear design but the 7A has less volume than highcomp or 20v. If fiting oil squirter in the 7A engine block use the smallport/20v pump for increase flow.

- Any 4A water pump to suit your configuration, RWD, FWD, electric fan, etc... search it's the same deal as any other 4A build

-Porsche 944 timing belt if using 16v head and I don't remember the one for 20v but refer to any 7A-GE build for that one, it's no different.

- Maybe forgetting some stuff

Keep in mind I'm still in the assembling phase. Engine as not run yet so power figures are just a guessing game. All we know is that the part fits so nothing should keep it from being succesfull. I'm pretty confident that the recipe is right and shouldn't create any problem but I'll need to report back with proof as soon as the thing is up and running.

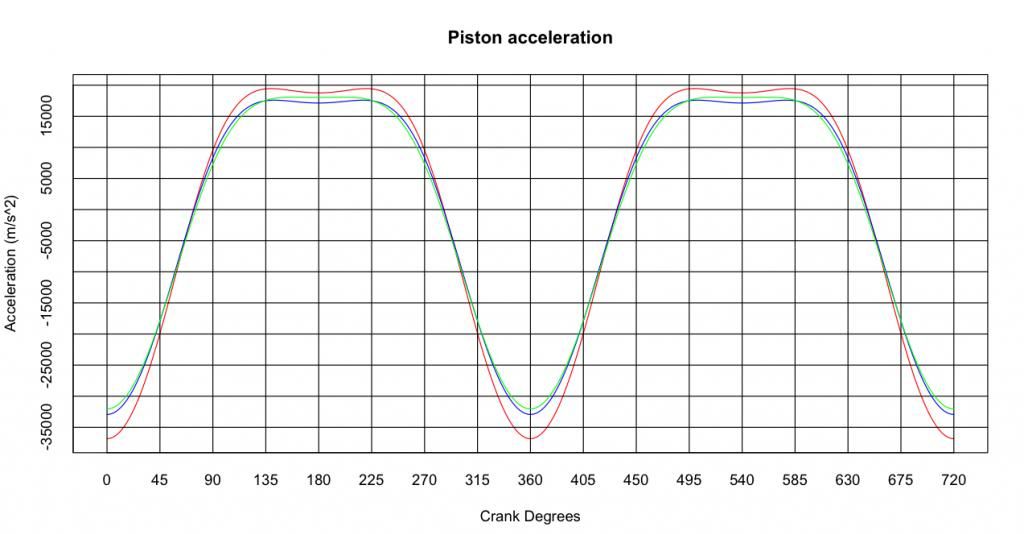

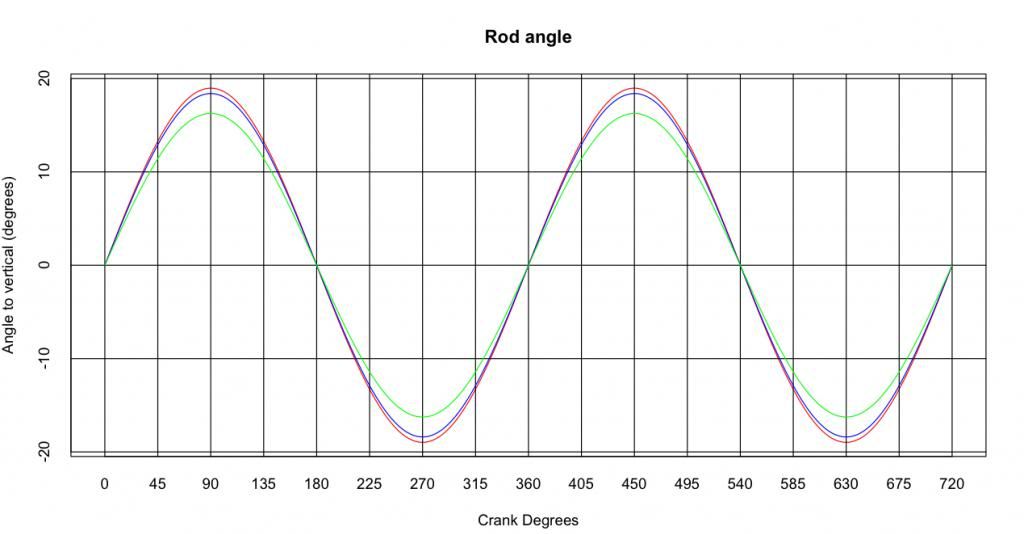

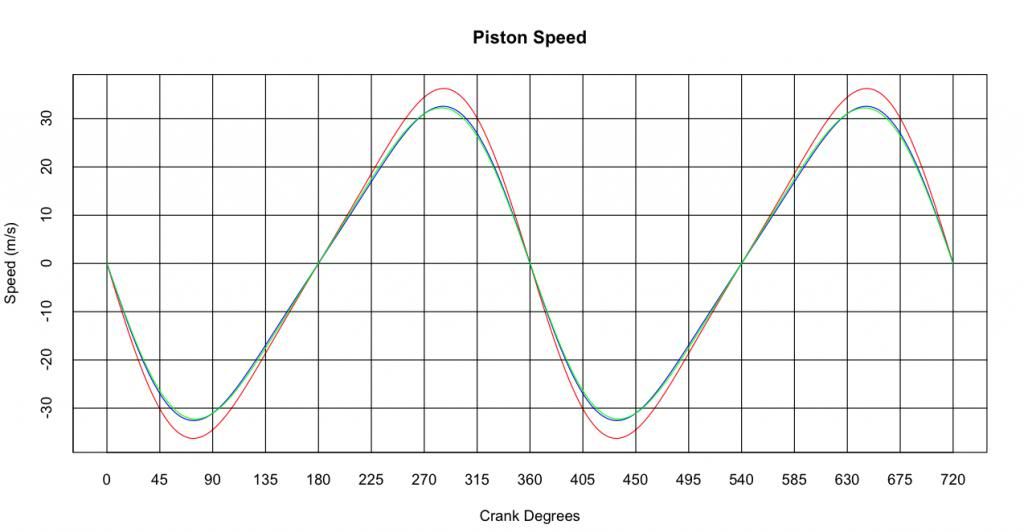

Oh and here are 3 graphs I made to compare rod angle, piston speed and piston acceleration... note that it's taken at 7700rpm (not important for the rod angle graph though...)

Red = 7A

Blue = 4A

Green = Tom-AGE

->

->

Reply With Quote

Reply With Quote

Not sure at what point the gains would be worthwile on this engine. 7000rpm? 8000rpm? 10000rpm? Will be interesting to see.

Not sure at what point the gains would be worthwile on this engine. 7000rpm? 8000rpm? 10000rpm? Will be interesting to see.

Bookmarks