Wow... big questionMaybe consider the FPR first as there are several things going on at the same time. Technically, the FPR is a pressure sustaining valve as its job is to try and maintain the upstream pressure at a constant level. And unless you have something pretty special, it will be a variation of this...

The vacuum reference is to compensate for changes in manifold pressure, so not relevant to constant speed operation. Basically the pump is opening the valve against spring pressure, and if the flow increases the valve will need to open a little more, and the spring pressure will increase slightly. The spring rate will be chosen so that the pressure increase over the valves design operating range is minimal.

Assuming that your FPR returns excess fuel to the tank, the pump should be pumping a constant mass of fuel and drawing constant current. NB: DC motors are voltage sensitive so the current will go up if the supply voltage goes down. The pump uses fuel for cooling and the fuel also picks up heat from the rail as excess fuel circulates between the tank and the engine.

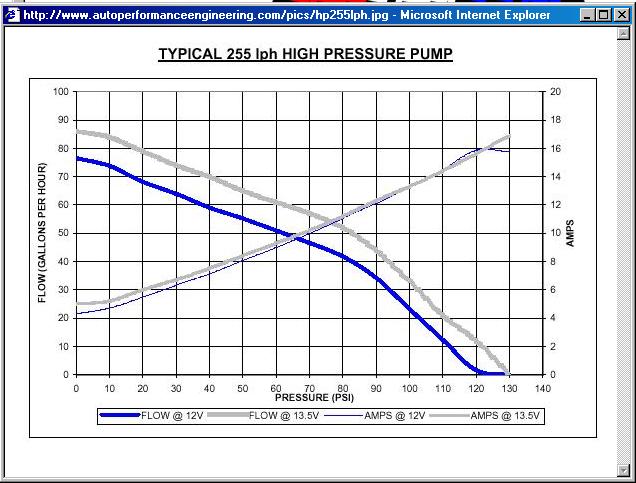

Raising the fuel pressure will put more load on the pump, and may shift its operating point to a less efficient point on its curve drawing more current. Fuel density will reduce as it heats up, and so mass flow will reduce. The net effect will likely be a small increase in current draw which will raise the pump operating temperature slightly.

Off the cuff I don't see why any of this should cause the rail pressure to drop unless there is some cavitation issue with the pump on e85 ?? Maybe someone else can explain.

EDIT: Doing a little digging on this subject (a bit of self-education) I see a couple of potential issues mentioned. Apparently e85 can cause problems with pumps not specifically designed for e85. The pumps relies on gasoline for lubrication, and the lesser amount of gasoline in e85 can cause premature failure of the pump.

As e85 requires the pump to flow at least 35% more volume than pump gas, it may not be able to keep up with demand causing pressure to drop off under high engine load. On the other hand, e85 appears to have a higher boiling point than gasoline, so pump cavitation is less likely to be a problem.

Cheers... jondee86

Reply With Quote

Reply With Quote

Bookmarks