An all-new exhaust manifold has been tuned to minimise exhaust gas flow restriction into the turbocharger and optimise the flow balance from cylinder to cylinder.

More turbine power has been extracted out of the exhaust gas, resulting in enhanced turbo responsiveness and further minimisation of turbo lag.

The reduced internal surface area of the new exhaust manifold maximises heat transfer to the catalyst, improving engine emissions by heating the catalytic converter faster after cold start-up.

Overall, the new exhaust manifold has delivered:

• a 14 per cent reduction in flow restriction

• a 10 per cent improvement in flow balance

• a 42 per cent reduction in internal surface area

• a 36 per cent reduction in weight

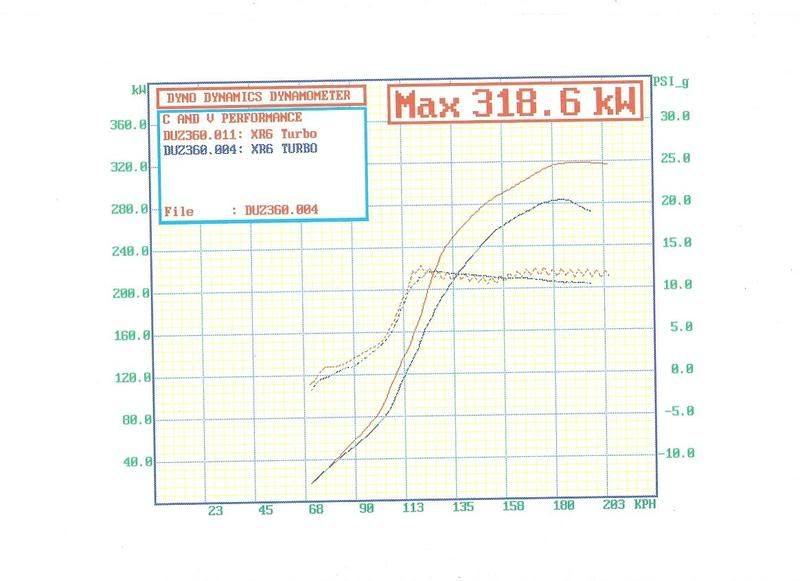

The net result of all the turbo system improvements is a significant increase to peak power and torque outputs on the new I6 Turbo engine, along with new levels of engine responsiveness and considerable gains in terms of fuel economy and efficiency.

Maximum power is up by 25 kW to 270 kW at 5250 rpm, while peak torque has increased by 53 Nm – or more than 11 per cent – to 533 Nm, which is available across a wide rev range from 2000 rpm – 4750 rpm.

Reply With Quote

Reply With Quote

. Nizpro Offers this as a further step after all other areas which offer cheaper gains have been exhausted. (I think its like stage 4 of their setups)

. Nizpro Offers this as a further step after all other areas which offer cheaper gains have been exhausted. (I think its like stage 4 of their setups) .

.

Bookmarks