Oh, and places in Brisbane that have a decent band saw...

Ok, so after finding out one of my 4AGE bigport heads is useless without the caps to hold the cams in, and now that I've sourced a new head, I've got a spare bigport head that I have no use for...

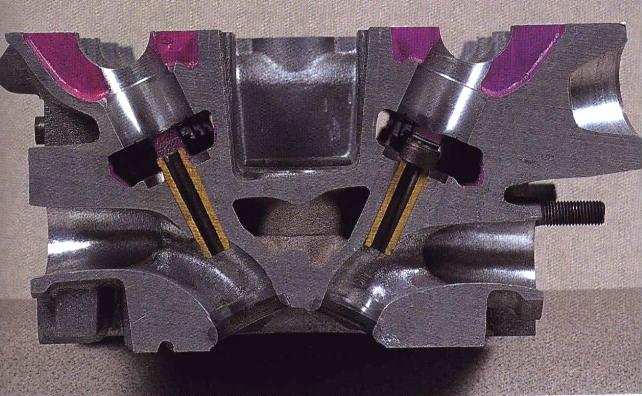

So I'm thinking of making a few cross sections then scanning them into the computer at 1:1 size so you guys can see exactly how much meat you can take out and work out improvements to the intake/exhaust runners.

Anyone interested? Got suggestions for cross sections? I was thinking of making a slice in line with a set of intake and exhaust valves in one chamber, and also straight through where the spark plug sits in another (both in the same direction of gas flow).

That leaves two spare chambers.

Tell me what you want!!

Oh, and places in Brisbane that have a decent band saw...

bah, be a man and use a hacksaw

slice a line running down the centre of the port and thru the valve guide/divider... to see roof and floor thickness and port contours..

on another, slice in 5mm sections, vertically, and perpendicular to length of engine..

then on another, do it vertically and parallel to length of engine.

oh and make sure you unmistakably mark distance on a surfae somewhere, so you know exactly where each slice goes (in relation to each other, so you can make up for lost thickness from blade)

"I'm a Teaspoon, not a mechanic"

"There is hardly anything in the world that a man can not make a little worse and sell a little cheaper" - John Ruskin (1819 - 1900)

AU$TRALIA... come and stay and PAY and PAY!!! The moral high horse of the world!

Yea the first two are what I (tried to) describe in my first post.

If I cut them every 5mm like you say, I could even create a 3D model of the port shape in the computer (CAD FTW!!)

Flow analysis anyone?

Just need the software to run the simulation...

ps. I would use a hacksaw, but my blade is broken. Maybe a steak knife will do?

that would be cool..it would be intersting to see how it is made up.Originally Posted by TERRA Operative

Good idea and it turns out interesting! i used a drop saw with a hose and a abrasive disc designed to cut cement/concrete. Good luck

just a suggestion, if you are cutting 5mm slices put a "v" shaped cut over them. This way you can easily see what order they go in and how far apart they need to be to allow for the cuts as oldcorollas mentioned. Sounds like an awesome idea, would be cool to get a few different heads done, 1g's etc.

Hello.

Good idea re. the V shape. Will do.

Anyone to donate spare heads??

OHHHHHHHHHHHHHHHHHH... love to see all these views.....

Concerning spare heads....I've got 2 junkers here... but "here" is 4000 miles away????????

Information is POWER... learn the facts!!

4000 could prove a problem...

I'm thinking of making a cast of the intake and exhaust runners from latex or similar, then cutting that up to get a profile. Would work out easier than cutting the head in 50 places I think.

I'll still do the first two cuts to see water galleries etc though.

What do you guys think?

Bill has had pics like this since the internet began!

http://www.billzilla.org/engcombust.htm

but a full model of everything on computer would be awesome, not that it's any good to me, but still awesome.

The spanner in my avatar is actually a 16mm, that's why it's still new

It'll look a bit like this ->

www.billzilla.org

Toymods founding member #3

mmmm 20valve cross section is porn.

It'd be really cool if you had access to a large mill.

Then you could mount the head in it, mill off 2mm, scan it and repeat.

From there it wouldnt be hard to make up a really good 3D model showing exactly where everything is.

It'd take time and machines like that are expensive though

If anyone has one I'd be willing to donate a head to the project though.

Cheers,

Terry

1987 AW11 MR2 Supercharger (4AGZE)

1974 TA22 Celica (2TG bored and stroked)

Thanks to James Cameron's Terminator films, we know that robots are stronger, faster, tougher and more Austrian than the rest of us.

Bookmarks