Pulling the shim out with the magnet.

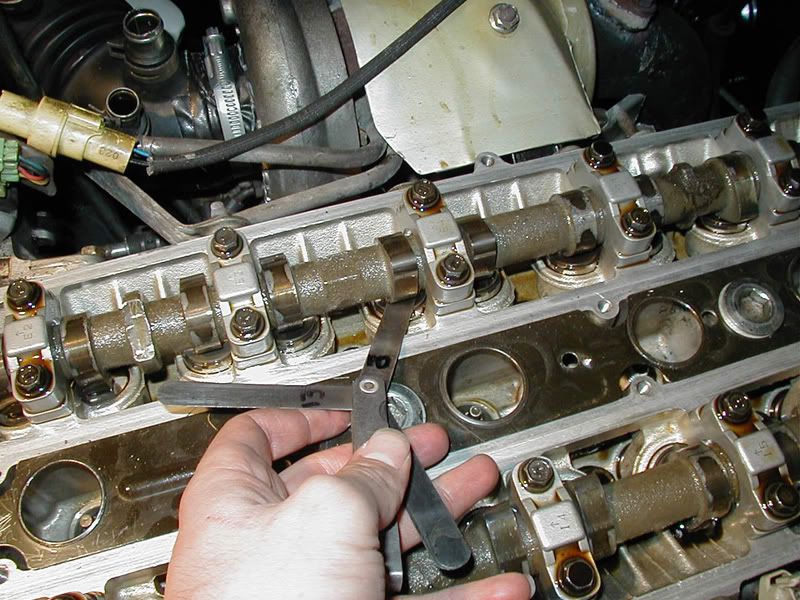

Measuring the shim.

I only measured the 1 shim at a time, so not to get the shims mixed up. Also if you have multiple shims out of the engine at once and you are turning the engine over, the cam lobes can enter into the recess of the bucket. If you keep turning the engine over the cam lobes will hit the side of the bucket and break them.

You can measure up to 8 shims before needing to turn the engine over to measure the next set of 8. Once you’ve done that you can move onto the calculations.

9. So once you have measured the shim clearances and the shim thicknesses, you can then work out the new shim size which you will need for each individual valve.

The formula to work out the new shims is:

Intake side: N = T + (A - O.20mm)

Exhaust side: N = T + (A - O.25mm)

N= Thickness of new shim needed

T= Thickness of the shim that was in there previously (Table No. 2)

A= The shim clearance that was measured (Table No. 1)

If you have taken measurements in imperial values this excel sheet can do all the calculations for you. This was written by my very helpful dad. Click here to download. Note, you will need to delete the values in there already from my own calculations.

10. Once you have the new shim sizes needed you may be lucky in that some of your old shims may be the correct size for some other valves, so you may be able to swap some around. When you know the amount of shims and sizes needed you can go down to the local Toyota or engine rebuilder and buy some. I paid around $12 for each shim at trade price from Toyota. I needed 17 of the suckers which made the exercise costly.

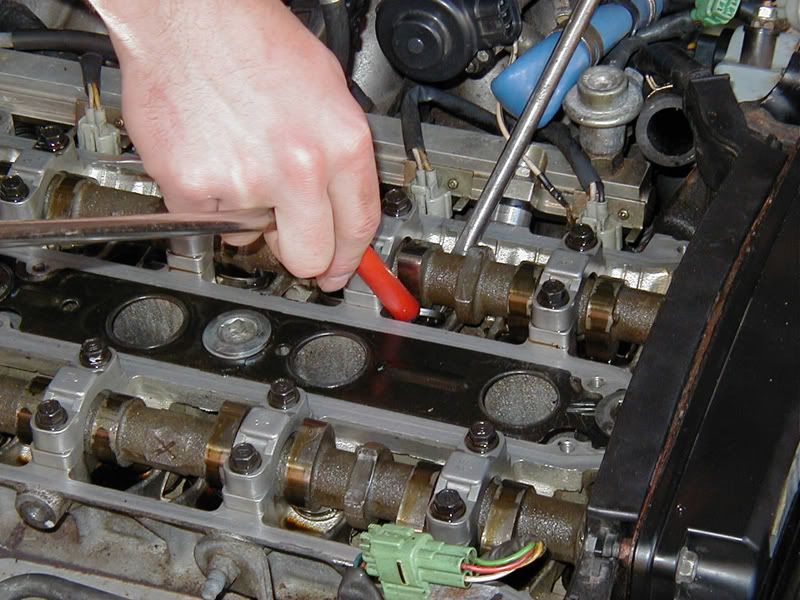

11. Once you have them, you can proceed and replace the old shims with the new shims you have. As again it’s the same process as measuring the shims, only you’re putting your new shims back in. Once all the necessary shims have been replaced, put the negative terminal back on (making sure you remove your ratchet from the crankshaft) and crank the engine over for 10 seconds or so. This is safe to do so while the cam covers are removed as there is not enough oil pressure to squirt oil everywhere. This is done to settle the shims into their places. Then re-check all the shim clearances just to double check your maths is all okay and everything is with-in spec.

12. Smile when all your shim clearances are with-in spec and you can now bolt everything back together again which is just the reverse of removing it all. But just before bolting everything back together again, i recommend checking the HG bolt torque's just to make sure everything is a-okay.

13. Then drive away knowing your not going to have a shim pop out while doing 200 clicks in 5th gear at the local race-track!

The exhaust clearances on cylinder 4 on my engine were 5 thou (.127mm) over the maximum spec. This caused a very rattly noise on idle which sounded much like a diesel. 17 of my shims needed replacing with new ones and I was able to swap 4 shims around. My idle is nice and quite now with no odd or unwanted noises.

Hope this helps a few doing their shims and if you have any questions ask away.

Cheers

Sam

Reply With Quote

Reply With Quote

Bookmarks