CHIPPING/MODIFYING THE HONDA ECU

This information is all borrowed from the PGMFI wiki, since they can 'splain it better than I can. The ECUs we're talking about here are the P06 (92-95 Civic EX, DX, CX), P28 (civic Si), P72 (92-95 Integra GSR) and P74/75 (92-95 Integra non-VTEC). There are a few others that work, but these are the most common.

You can do this yourself if you're handy with a soldering iron, or there are plenty of people out there who will perform these services for you for a price.

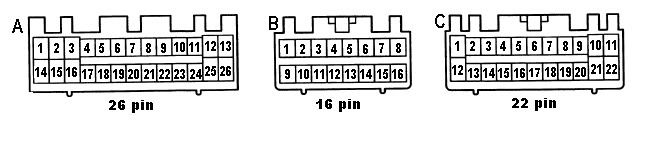

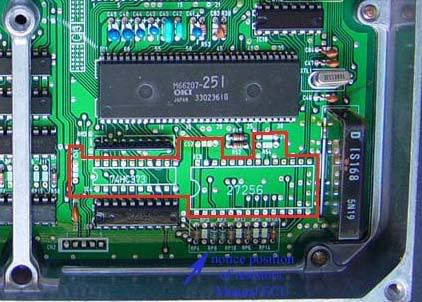

Honda was nice enough to tell us how to do it:

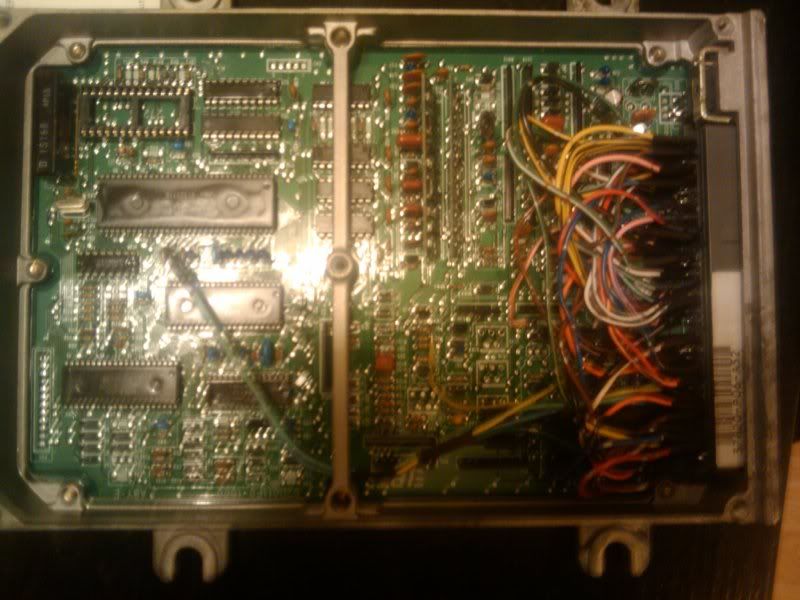

We're basically just populating the portion of the board within the white dashes with the components listed. Desolder the holes (RadioShack sells a desoldering iron that works very well for <$15:

)

28 pin EPROM (www.moates.net carries chipping kits for ~$15-20)

74HC373 octal latch.

C51 and C52 are 0.1uF capacitors

R54 is present on some boards, not present on others. It is 1k ohms.

J1 is a wire jumper to tell the MCU to use the external ROM.

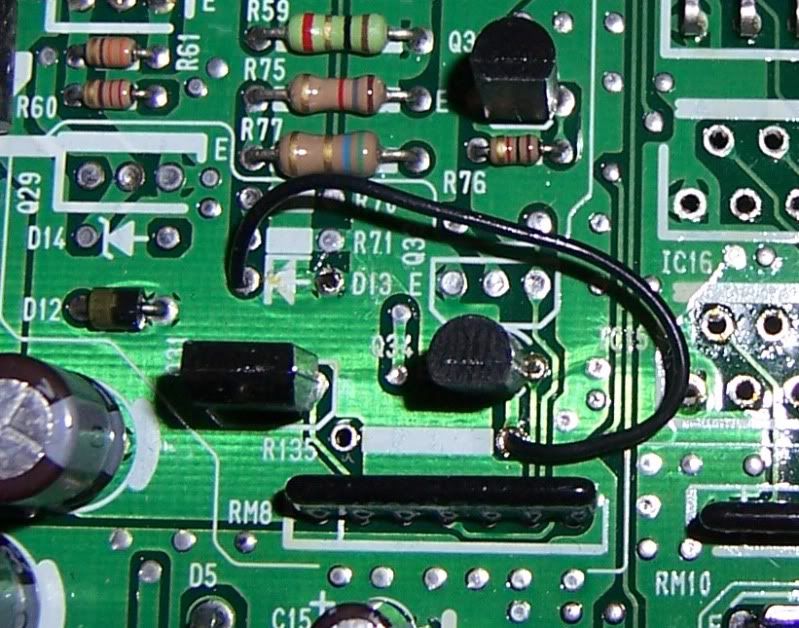

If you happen to have an ECU from an automatic, you can convert it to manual by removing RP17 and RP18, and soldering in a jumper where RP18 used to be:

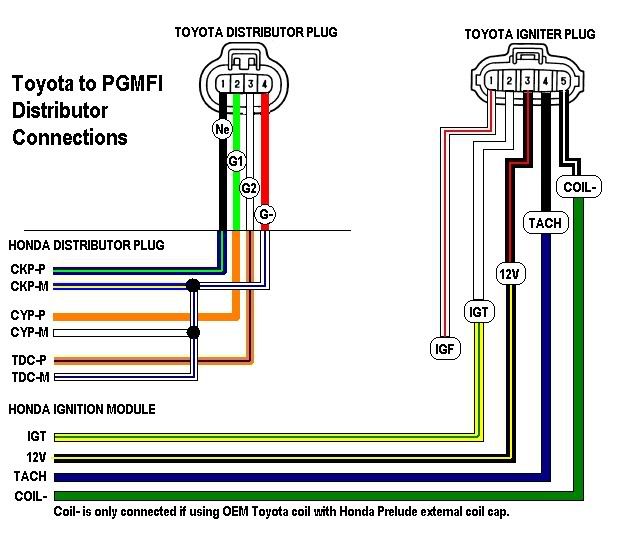

Add TVIS/IAB functionality (from the PGMFI wiki):

- Q17(A143)...already present on USDM auto 11F0/1720 (A5x, L5x, etc). Not present on EDM auto 11F0/1720 (G5x, etc).

- Q34(D1780 or C3225?)... already present on USDM auto 11F0/1720 (A5x, L5x, etc). Not present on EDM auto 11F0/1720 (G5x, etc). May use PCS trans: Q31(D1780)

- Jumper from right hole of R135(trans side) to D13(arrow side):

There are more mods listed in the wiki, such as adding the VTEC hardware (staged fuel injection, antilag, etc) and modding other ECUs like the P05.

PGMFI hardware mods WIKI

Reply With Quote

Reply With Quote

Bookmarks