Maybe email Ross, ask them if they have rings, and what the effect of running 1.2mm rings would be?

Hey

Sorry for the late reply. Remember at the time of getting the rings that I could only find 1.5mm rings with 2.5 or 4mm oil rings. Accrilite ones were all i could find that would "fit".

Got 60 - 65 psi cold oil pressure, last time i had the cam cover off there was loads oil.

Made another video and now im thinking its more valve train related? Also noticed the flywheel cover where the engine meets the gearbox sounds like a tambourine when I tap it. Gonna try sound deadening this plate.

Added some octane booster, and its reduced the audible knocking pulling away.

The guy I bought the box of engine bits off said the pistons where 9.0:1. So if they are 8.5:1 with the 1mm gasket n the light skim im probably only 8.8:1 ish then

Have a listen n see what you think.

https://m.youtube.com/watch?v=sYpZyANYyE8#

Thanks again.

Chris.

Maybe email Ross, ask them if they have rings, and what the effect of running 1.2mm rings would be?

"I'm a Teaspoon, not a mechanic"

"There is hardly anything in the world that a man can not make a little worse and sell a little cheaper" - John Ruskin (1819 - 1900)

AU$TRALIA... come and stay and PAY and PAY!!! The moral high horse of the world!

SOLVED IT!!!

Second time now since the new engines been in number 1 exhaust shim moved!?!?! Spat out number 4 last hence the dead cylinder saga...

ALL clearances where in spec. Checked n double checked. What gives???

Intake 0.15mm - 0.25mm

Exh 0.25mm - 0.35mm.

The first exh valve was less than 0.20mm n was missing on that cylinder?

Any ideas? Whats usually the deal spitting shims while "in spec"

Forgot to say alledgly they are JUN valve springs. Would stronger springs make a diffrence? Thought it would help!

My sh#tty workmanship? Lol or dud valve stem? (Shims were all new).

Thanks

Chris

Last edited by Blackcountryboy; 04-04-2018 at 06:38 AM.

Just for clarification... what does "moved" mean ? As I gather you have a shim over bucket setup, for the shim to go anywhere it has to jump over a little wall on top of the bucket. So, did the shim put one foot on top of the wall or did it jump right off the bucket ?

If it is doing that one might expect to see the edge of the shim lifting when the engine was slowly rotated by hand. How much lift/duration is there on the exhaust cam ? Does the shim have a convex surface allowing it to rock on the bucket ?

Cheers... jondee86

Hey Jon

Its a 9mm lift HKS 256 cam. All the shims where new from Mr T.

The clearance has closed up so at this stage (ran outta time yesterday before work to strip the head... Again... think its put a foot ontop of the wall. Valves are unknown. Stock retainers. Springs where said to be JUN.

Got a quote from Oz for £117.20 delivered for a full set of 1zz shimless buckets. Worth it?

Got a week off work coming up, think im gonna re do all the clearances. Check n triple check n try n get them all closer to 0.25-0.30. Non where over 0.35

Never revved over 3k since building it.

Was still pulling 18hg while "missing" on no 1 cylinder, n missed audidbly every 4th rotation.

Think I got lucky on my first build. If I'd known the 2nd one would have been such a nighmare id have just gone to the pub instead.

Thanks again for helping me. The folks on here are great n I appreciate every bit of advice.

Cheers

Chris

https://youtu.be/rplE6vvzAY4

https://m.youtube.com/watch?v=s35ap1-2hoA#

Last edited by Blackcountryboy; 04-04-2018 at 09:22 PM.

Still thinking about why one valve clearance would close up so fast after doing the exh valve stem seals a month or so back... N rechecking the clearances...

I'm probably way off but here goes...

Maybe the valve seat got carbon'd up just idling in the garage for ages, the clearance opened up, and the offending shim "put a foot on the wall" as Jondee said.

Maybe cos their uprated valve springs one valve seat got "hammered" and the clearance closed up? Unlikely but until the cams com out again tmrw its all guess work.

If it was too loose I'd seafoam the head to see if the clearances closed up a little. Bugger.

The other vid is of the plugs (all four are light brown, n a bit sooty rich).

Anybody else had valve clearance s change (tighten) before a builds even got any miles on it?

After months of chasing ghost vacuum leaks, dead cylinders, and knocking noises im thinking it may be down to the head.

It was professionally rebuilt by a machine shop less than 1k ago. I just shimmed it to spec the best I could n added the high lift cams.

Does any of this sound possible?

Thanks

Chris

I did wonder about the exhaust note in your vid... certainly sounded irregular. But I was impressed by the way the engine settled back to idle after you gave it a bit of a rev.

Before you start pulling cams out you need to investigate as thoroughly as possible. Do a compression test. Get something like a dental mirror and a torch and look under the cam to see if there is anything unusual visible. If the shim had a foot on the wall you would have zero clearance and no compression, and you could see the shim sitting at an angle. Try and get a feeler gauge in at either side of the cam lobe and see if one side has more clearance than the other.

That HKS cam should be fine with shim over bucket, and there has to be some physical reason why you are getting a problem with that particular valve. Valve or bucket tight and sticking... debris under shim... broken valve spring... a reason.

EDIT: Wait.... just read this thread again and am I right in thinking that you are saying all that happened was the clearance on that one valve went from (say) 0.30mm to 0.20mm ?? Shims are usually in the 2.5 - 3.0mm thick range, so if you spit a shim out only the top of the lobe is giving the bucket a whack as it goes past.

I'd be surprised if the clearance closing up to 0.20 would be enough to hold the valve off its seat and cause a miss. But those plugs look kind of ugly and it wouldn't take much more than cold start enrichment to wet one of those and stop the cylinder firing.

Cheers... jondee86

Last edited by jondee86; 05-04-2018 at 05:40 PM. Reason: Second thoughts...

And check those thin rings.

Would suck to chew out the bores first time you get the revs up..

"I'm a Teaspoon, not a mechanic"

"There is hardly anything in the world that a man can not make a little worse and sell a little cheaper" - John Ruskin (1819 - 1900)

AU$TRALIA... come and stay and PAY and PAY!!! The moral high horse of the world!

i'd change immediately those rings, you will damage the pistons and the bores if you keep those rings, get the correct ones, total seal makes nice rings, look it up or je rings, which are total seals

for the valve clearance, it's normal for it to close a bit after being machined etc, on a freshly machined head always set the gap to the maximum value, as for why it spit up a shim, unless the cam is too aggressive, i'd say it simply wasn't sitting properly, that could also possibly explain the discrepancy in the clearance, to make sure it sits right try to spin the shim in the bucket, if it doesn't it's not sitting properly

also make sure that the bucket is actually touching the tip of the valve and not the retainer cap, sometimes when using different parts here and there it could happen

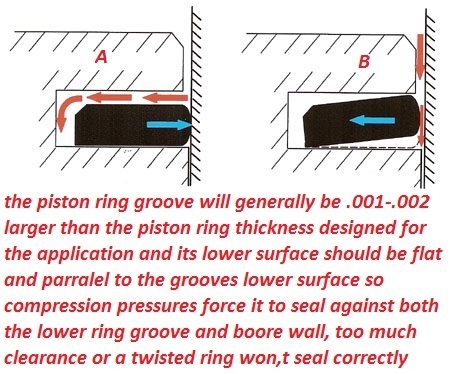

What he ^^^^ he said. Due to the rapid reversal of the pistons with each cycle, the rings (which tend to want to stick to the cylinder wall) are pressed alternatively against the top of the ring groove and then against the bottom. Eventually, the harder ring will wear away the softer aluminum, causing the ring groove to become wider. The wider the groove, the greater the impact of the ring on the piston, and the faster the groove wears.

By installing a narrow ring with excessive side clearance, you have essentially started out with substantially worn grooves. If a used piston was found to have as much clearance as you have with your new pistons, it would be consigned to the bin.

This pic shows another problem...

Excessive side clearance allows the rings to twist in the groove so that they no longer sit perpendicular to the cylinder wall (as they was dsigned to sit), and their function will be impaired.

Regarding the shim clearance... is it possible that one of the collets is not fully seated ?

Cheers... jondee86

Hey all

Sorry again for the late reply.

Have done some searching from 2016 in my ebay purchase history and have found the rings i used.

They were Hastings 86,5mm racing ings p/n 2C 4653 020

1.2mm

1,5mm

4,0mm

apparently OE std sizes for the 3sgte? So ive goosed up totally by fitting the top ring, or so i think... (trying to remember what i did buying, gapping and fitting them, just remember they were the closest match i could find... this is prob a wake call to take the beer fridge outta my man cave/engine building spare room where i built it on the stand).

A month before, looking back at ebay id bought a set of NPR japan rings, the same sizes (1.2, 1.5, 4) and remember i broke one the top rings whilst fitting them whilst taking an ear bashing off the wife lol, , so i bought the hastings set to try again when she was out ; )

I have a vague recolection of using the NPR 2nd 1.5mm rings in the top instead of the thinner 1,2mm Hastings rings, so essentially i made all the rings fit. From what i remember... Shocking i know.

Am i good if this the case? or would this be even worse? All dots would have been upwards, gaps staggered.

Cant face dropping the complete subframe, engine n gearbox again on my drive to swap em. Gonna have to wiggle the engine in situ, take of the head an drop the oil pan then try n take the pistons out the top?

Inspected the offending exh shim thats tightened up for some unfathamable reason.. 0.15 - 0,20mm. No bucket movement side to side and the shim was dead centred when i took out the bucket. Got a 0.10mm thinner one from Mr T this week.. Cams where covered in oil n everything looked good.

Did a cold compression test while the valve cover was off. 155 on the dead cylinder. All turned nice, sounded good, I also turned the crank by hand and nothing was holding up, or sticking. What gives. Gonna try n get her back together tommorow if it ever stops raining, to see it this gets rid of some of the valve train noise...

Am thinking this might just be a good excuse to build a 5Sgte stroker (or pay someone more sober who actually knows what their doing) and bite the bullet with this build!

Thanks again

Chris

According to this information from the Federal-Mogul site, you are either good or pretty good if you have the 1.5 rings in the top ring groove. How good just depends on the type of ring installed

Rectangular Ring:

A piston ring with a rectangular cross section. This ring with its geometrically simple shape performs the necessary sealing functions under normal operating conditions. With a peripheral coating and appropriate barrel face the rectangular ring is today used mainly in the top groove in passenger car gasoline and diesel engines. Besides service in internal combustion engines, rectangular rings are commonly used as rotary shaft seals, e.g. transmission seals [1].

Taper Faced Ring:

Owing to the tapered running face the ring contacts the cylinder bore with its bottom outer edge. This shortens running-in and improves oil scraping. The gas forces acting initially at the running face provide a degree of pressure relief (especially when used in the top groove). Taper faced rings are chiefly installed in the second groove in passenger car gasoline and passenger car and truck diesel engines. In passenger car gasoline engines they are also used in the top groove.

Cheers... jondee86

Hey all,

https://m.youtube.com/watch?v=eB1gLymQhh0

Put the new 0.05mm shim in. Can just get a 0.25mm gauge in there now... Just...

Put her all back together. Have a listen! Sounds loads better!

Vacs dropped from 20 to 12 hg so suspect the cam timings off slightly.

Went through all the old left over rings I have in the spsre room. Am 99% sure ive canabslised 3 sets to get the right rings in there.

Afr was 11.1 cold goes to 13.2 at warm idle. Closed loop turned off for now. About right?

Thanks again for everyones advice/hell!

Chris

Looks like you are going to get to enjoy your car after all the hasslesPut some miles of ordinary driving on it; not babying it but not beating on it either. Check for any leaks or abnormailties and then use it how you like !!!

That AFR is a bit low for warm idle. I'd suggest low 14's if your engine is happy with that. I usually shoot for 14.3 or 14.3 as most engines like to idle a bit richer than stoich. But get your timing sorted first as that will most likely change the idle AFR.

Cheers... jondee86Permanence, perseverance and persistence in spite of all obstacles, discouragements and impossibilities: It is this, that in all things distinguishes the strong soul from the weak.... Thomas Carlyle

Last edited by jondee86; 15-04-2018 at 03:12 PM.

Bookmarks