Update time.

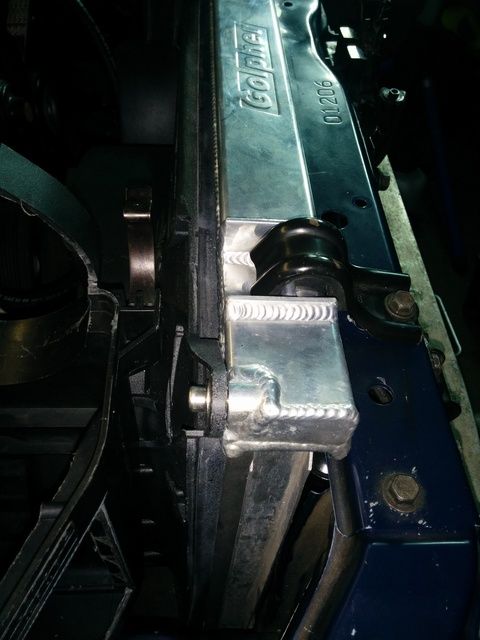

Firstly, there was a small fuck up with the tailshaft. I thought only the front section was going to require modification to suit the gearbox. I'd been operating under the assumption that the IS200 and IS300 diffs were the same length. Unfortunately, this was not the case. The IS300 diff was about 15mm longer. So rather than working any further on it, Pete dropped the whole lot at the local driveshaft shop and had the rear section remade with new Hilux uni joints and got them to weld the CV stub into the front shaft and then balance the whole lot. I picked it up this morning.

Then we installed it.

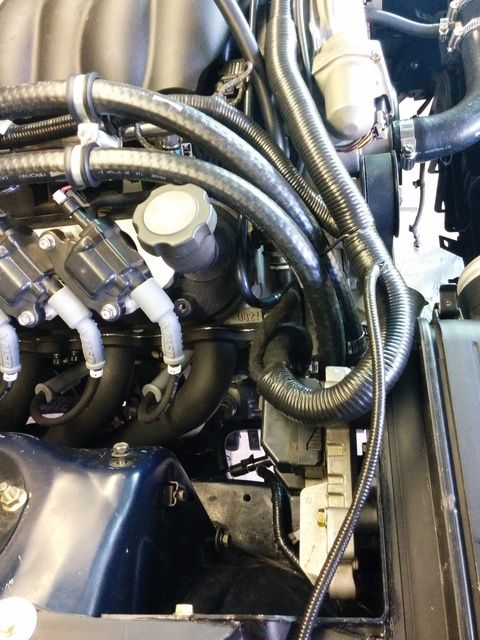

We were able to install it because I had picked up the headers from ceramic coating on Tuesday morning and dropped them down to Pete and he had installed them on the engine and bolted the engine into the car for (hopefully) the final time. I haven't got any pics of the coated headers out of the car yet as it was a drop and run. But Pete took some so I'll post them up soon. Here's how they look in the car.

Reply With Quote

Reply With Quote

.

.

Bookmarks